What is a tins shredder?

What is a tins shredder?

Table of Content

- A Tins Shredder

- Key Features ofA Tins Shredder

- How does A Tins Shredder Work?

- Factors Influencing A Tins Shredder Price

- FAQs about Tins Shredders

- Conclusion

A Tins Shredder

A tin shredder is designed to handle a variety of materials, primarily focusing on metal containers and other metallic waste. The types of materials a tin shredder can deal with include:

Primary Materials

-

Tin Cans:

- Food cans

- Beverage cans

- Paint cans

-

Aluminum Cans:

- Soda cans

- Beer cans

-

Steel Cans:

- Soup cans

- Vegetable cans

- Oil drums (depending on the shredder’s capacity)

Additional Materials

-

Light Metal Scraps:

- Small metal parts and components

- Sheet metal offcuts

-

Aerosol Cans:

- Deodorant cans

- Spray paint cans (ensure they are empty and depressurized)

-

Metal Foils:

- Aluminum foil

- Tin foil

-

Metallic Packaging:

- Foil trays

- Metal lids and caps

-

Non-Ferrous Metals:

- Copper cables (though a specialized cable shredder might be more efficient for this)

- Brass

- Zinc

Considerations

- Material Size and Thickness: Ensure the shredder is capable of handling the size and thickness of the material. Some materials might require pre-processing or size reduction.

- Material Composition: Different metals have different properties, and the shredder must be equipped to handle them without excessive wear or damage.

- Hazardous Materials: Items like aerosol cans or electronics may require special handling to avoid releasing harmful substances.

By configuring the shredder appropriately and ensuring it is designed to handle the specific types of materials you need to process, a tin shredder can be a versatile and efficient tool for recycling and waste management.

Key Features of A Tins Shredder

-

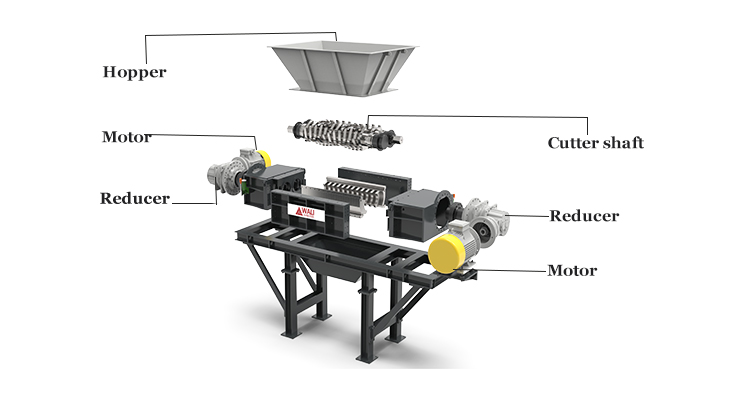

Robust Construction:

- Made with durable materials to withstand the rigors of shredding metal cans.

-

Powerful Motors:

- High-torque motors capable of handling thick and sturdy tin materials.

-

Cutting Mechanism:

- Sharp, durable blades or hammers that can efficiently cut through tin.

-

Feeding Mechanism:

- Hopper or conveyor system for continuous and easy feeding of tins into the shredder.

-

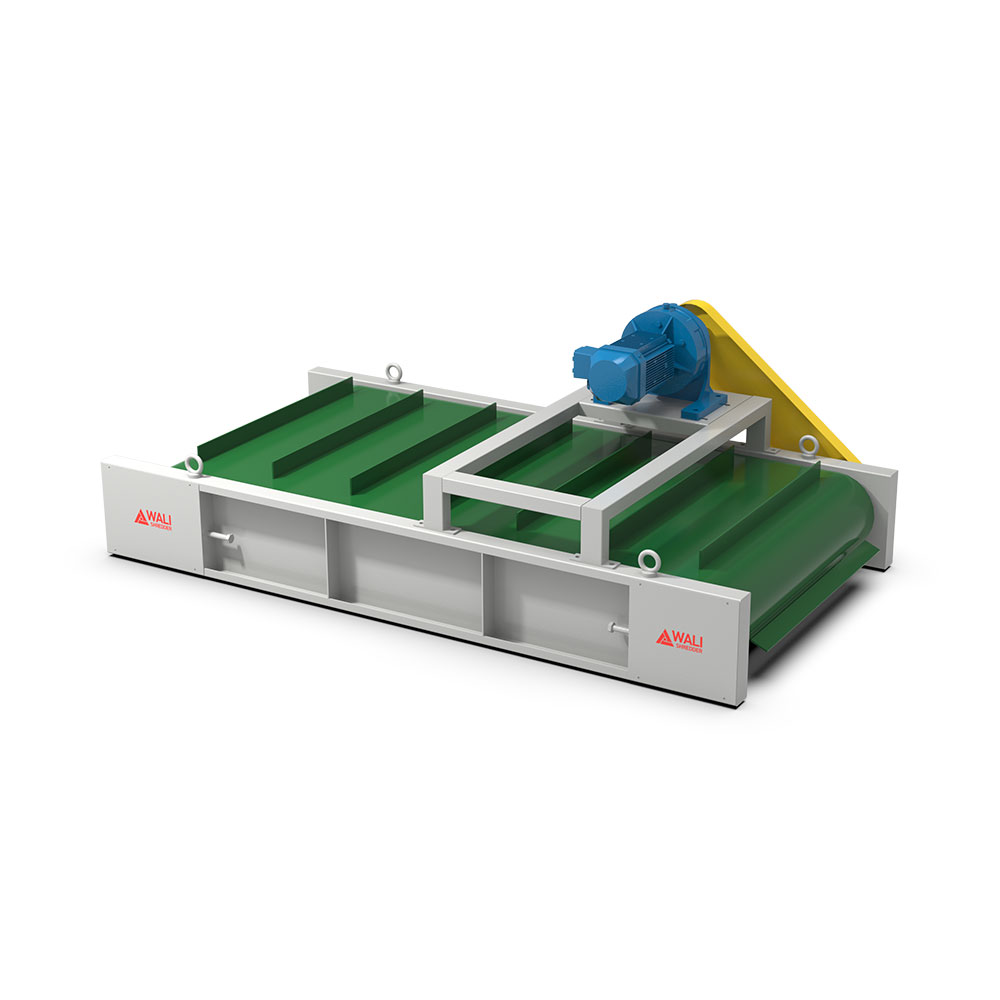

Separation Technology:

- Magnetic separators to remove ferrous materials.

- Granulators for reducing the size of shredded material.

-

Control System:

- Automated controls for efficient operation.

- Safety features such as emergency stop buttons and overload protection.

-

Dust and Noise Reduction:

- Systems to minimize dust emission and noise during operation.

-

Additional Equipment:

- Dust Extraction Systems: To manage dust and maintain a clean working environment.

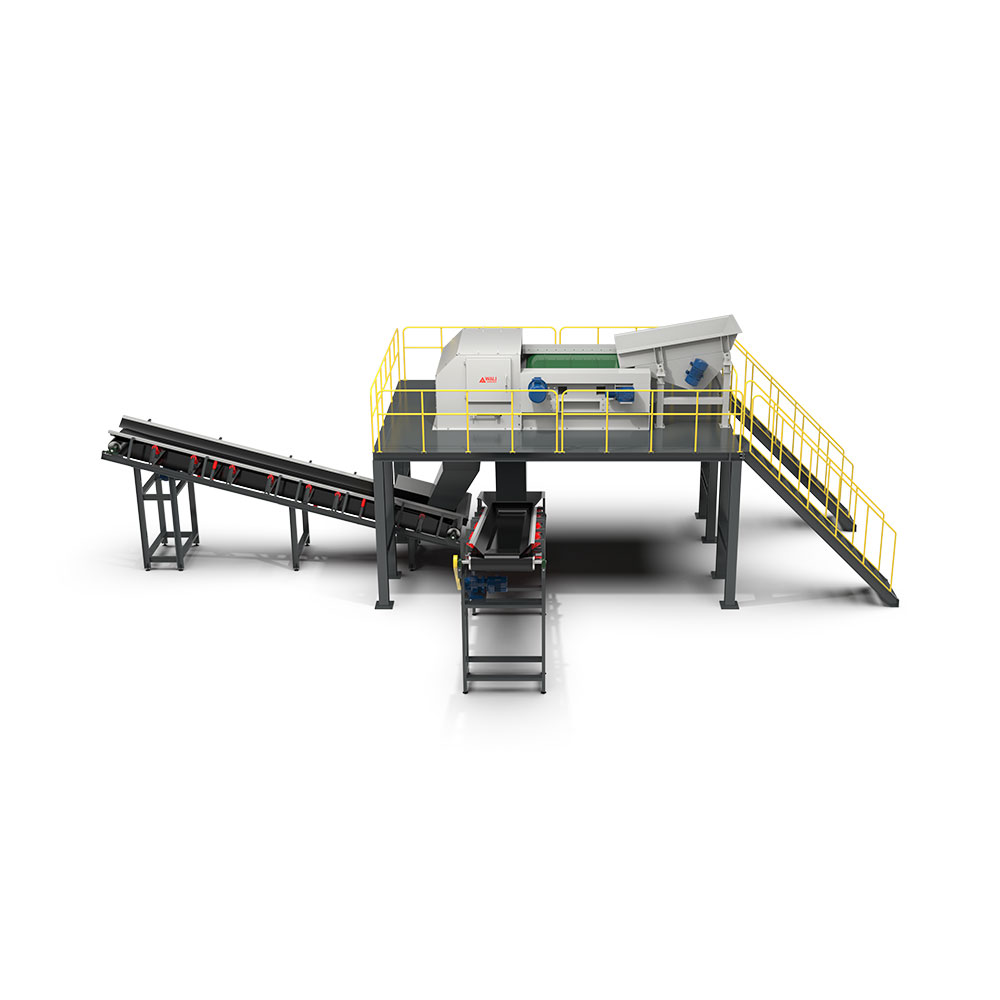

- Output Conveyors: For transporting shredded material to further processing stages or storage.

-

Capacity and Throughput:

- Shredding Capacity: Based on the expected volume and type of tins to be processed.

- Throughput Speed: Adjustments to balance processing speed and efficiency.

-

Energy Efficiency:

- Energy-Saving Modes: To reduce power consumption during idle times.

How does A Tins Shredder Work?

A tins shredder operates through a series of mechanical processes designed to efficiently break down and separate tin cans and other metal containers.

-

Feeding

- Input Material: Tin cans and other metal containers are fed into the shredder.

- Feeding Mechanism: This can be done manually, via a hopper, or using a conveyor belt for continuous feeding.

-

Shredding

- Cutting Mechanism: The shredder has rotating blades, hammers, or drums that chop the tin cans into smaller pieces. These blades are usually made from high-strength steel to handle the tough metal.

- Shredding Process: As the tin cans pass through the cutting mechanism, they are sliced and torn into smaller fragments. The size of these fragments can be adjusted by changing the configuration of the blades or screens.

-

Separation

- Magnetic Separation: Once the cans are shredded, the material passes through magnetic separators to remove any ferrous (iron-based) metals. This helps in separating different types of metals for recycling.

- Granulation (Optional): The shredded tin pieces may be further reduced in size by granulators, which ensure a uniform size for easier processing.

-

Collection

- Output: The shredded tin fragments are collected and can be directed to different bins or containers. This output can be further processed or transported to recycling facilities.

- Conveyors: Output conveyors may be used to transport the shredded material to the next stage of processing or storage.

-

Additional Processing (Optional)

- Air Classification: This technique uses air flow to separate lighter materials from heavier metal fragments.

- Eddy Current Separation: This method uses magnetic fields to separate non-ferrous metals (such as aluminum) from other materials.

-

Control System

- Automation: Modern tins shredders come with automated control systems that monitor and adjust the shredding process for optimal performance.

- Safety Mechanisms: Emergency stop buttons, overload protection, and safety guards ensure the machine operates safely.

By following these steps, a tins shredder effectively reduces the volume of tin cans and other metal containers, making them easier to handle, transport, and recycle. This process not only aids in waste management but also contributes to environmental conservation by enabling the recycling of valuable metals.

Factors Influencing Tins Shredders Price

- Tins Shredders Configuration

- Blade Type and Material: Different shredders use various blade configurations and materials (e.g., steel) for durability and efficiency.

- Motor Power: Ranges from 50 HP to over 500 HP depending on the shredder’s size and capacity.

- Brand and Manufacturer: Reputable brands with a history of reliability and performance will significantly impact its cost.

- Customization: Machines tailored for specific applications or with special configurations may be more expensive.

-

Additional Costs

- Shipping and Transportation: Depending on the location, transporting a large tire shredder can add several thousand dollars to the total cost.

- Installation and Setup: Professional installation and setup will be an expense.

- Maintenance and Spare Parts: Ongoing maintenance and the cost of replacement parts should be factored into the overall budget.

FAQs about Tins Shredders

Q:What are the benefits of tins shredders?

A: Enables the extraction of valuable metals like copper, aluminum; reducing costs in transportation and storage.

Q: What is the price of a tins shredder ?

A: The price of a cable shredder can vary significantly depending on its size, capacity, discharge size, motor brands and so on.

Conclusion

Tins shredder are essential for resource recovery, helping to reduce waste and recycle materials efficiently. When purchasing a tins shredder, it’s important to consider factors such as the type and volume of tins we need to process, the machine’s capacity and features, after-sales support, and warranty.

Wali Shredder

Wali Shredder