What is a car radiator shredder?

What is a car radiator shredder?

สารบัญ

- Car Radiator Shredders

- How Car Radiator Shredders Work

- Key Components of a Car Radiator Shredder

- คุณสมบัติด้านความปลอดภัย

- Factors Influencing Car Radiator Shredders Price

- FAQs about Car Radiator Shredders

- บทสรุป

Car Radiator Shredders

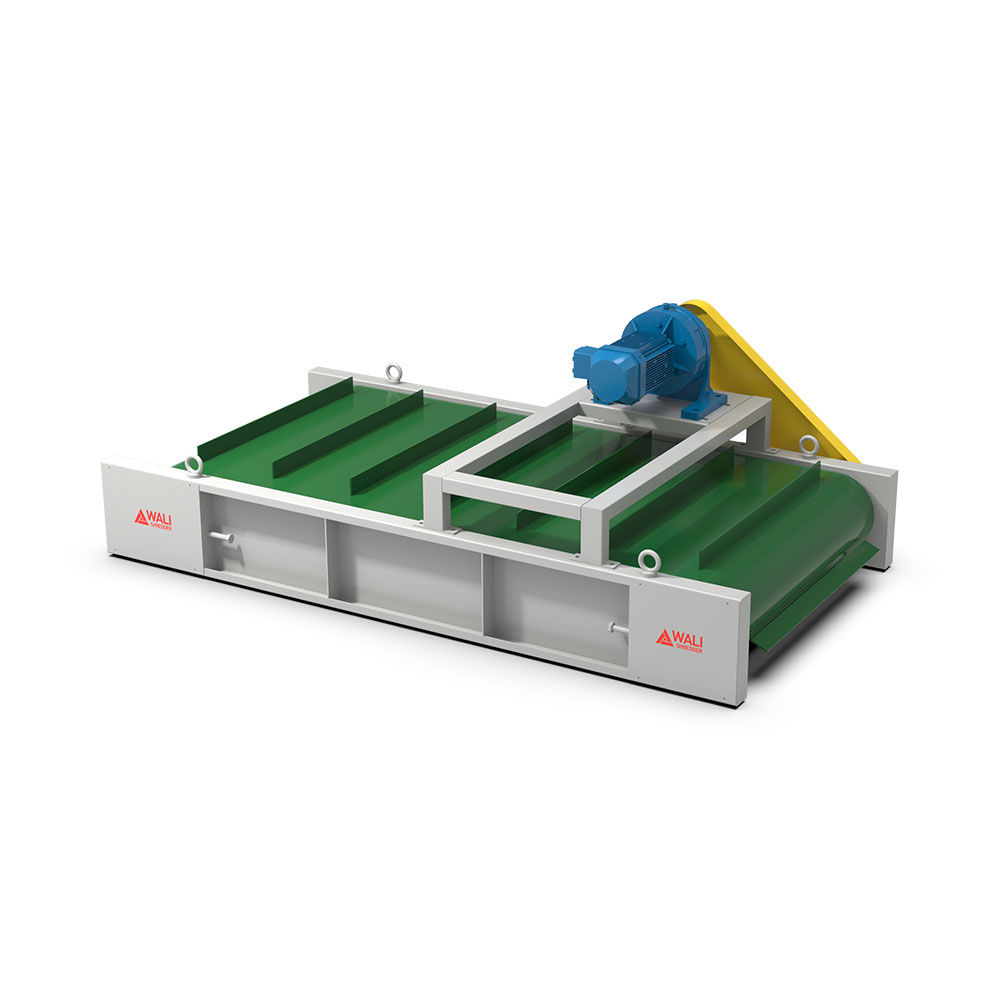

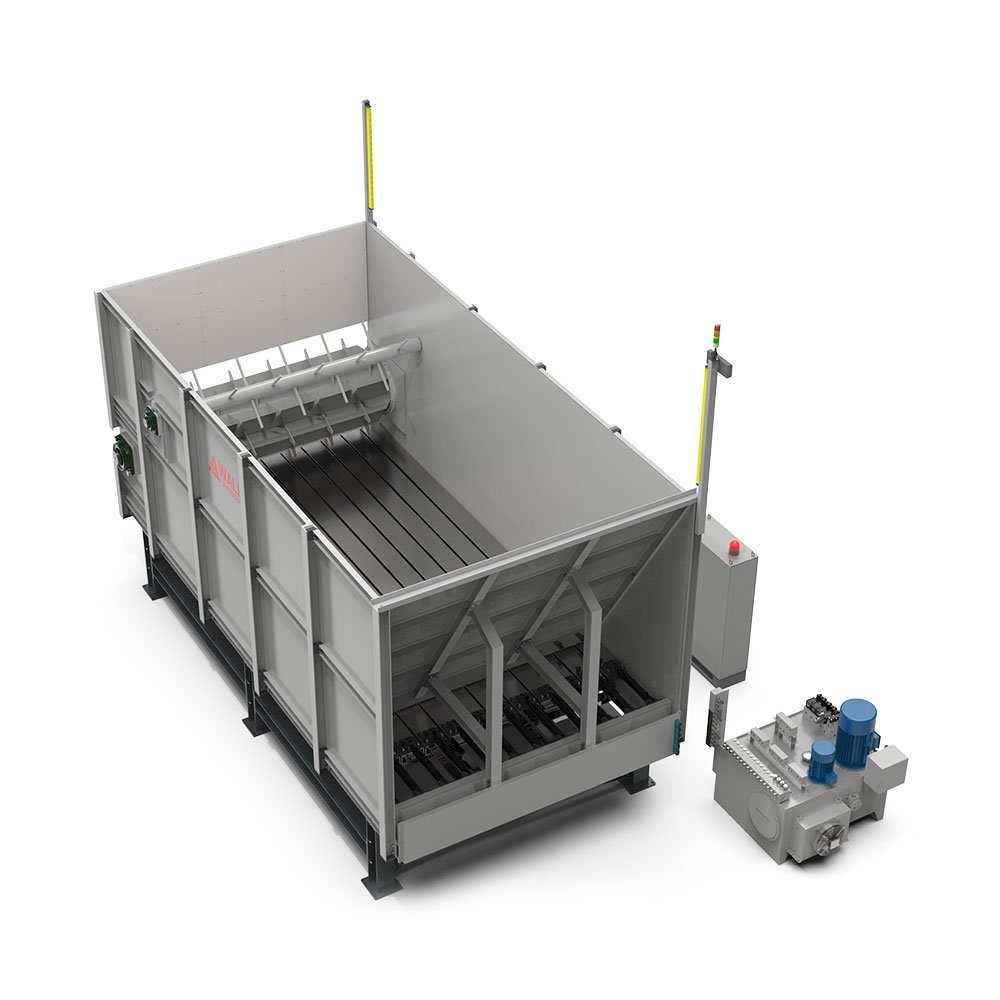

A car radiator shredder is a specialized machine used for recycling radiators from cars, HVAC systems, and other sources. It efficiently separates valuable metals like copper, อลูมิเนียม, and steel from other materials, facilitating the recycling process.

How Car Radiator Shredders Work

-

การให้อาหาร:

- Radiators are fed into the shredder, either manually or via a conveyor belt in larger operations.

-

Primary Shredding:

- Blades/Cutters: The radiator passes through rotating blades or cutters that slice it into smaller pieces. These blades are typically made of high-strength steel to handle tough materials.

-

Initial Separation:

- The shredded material is discharged from the shredder, usually onto a conveyor belt that transports it to the separation systems.

-

Separation Systems:

- การแยกแม่เหล็ก: Removes ferrous metals (like steel) using powerful magnets.

- Air Separation: Uses airflow to separate lighter materials (such as plastic or dust) from heavier metals.

- Vibration Separation: Uses vibrating screens to sort materials by size and density.

-

Secondary Shredding (Optional):

- Some systems include a secondary shredding stage to further refine the material size and ensure complete separation.

-

Final Separation and Purification:

- Eddy Current Separator: Separates non-ferrous metals (เช่นอลูมิเนียมและทองแดง) using a magnetic field.

- Density Separator: Separates materials based on density using water or air.

-

Collection and Storage:

- Separated materials (เหล็กกล้า, copper, อลูมิเนียม, พลาสติก) are collected in different bins or conveyors and stored until transported to recycling facilities.

-

Cleaning and Refinement:

- The separated metals may be washed to remove contaminants, and manual sorting may be done to ensure purity.

Key Components of a Car Radiator Shredder

- Blades/Cutters: Made from high-strength, wear-resistant materials.

- Motors and Drives: Provide the power needed for shredding.

- Conveyor Belts: Transport radiators into the shredder and move shredded materials to separation systems.

- Control Systems: Monitor and adjust the operation for safety and efficiency.

- Dust and Noise Control: Manage emissions and reduce noise for a safer working environment.

คุณสมบัติด้านความปลอดภัย

- ปุ่มหยุดฉุกเฉิน: Quickly stop the machine in emergencies.

- ยามรักษาความปลอดภัย: Protect operators from moving parts.

- Sensors: Detect blockages or jams and automatically shut down the machine.

Benefits of Car Radiator Shredders

- Efficient Recycling: Maximizes the recovery of valuable metals, reducing waste.

- Environmental Impact: Minimizes the environmental footprint by efficiently processing and recycling materials.

- Economic Benefits: Recovers valuable metals that can be sold or reused, offsetting the costs of recycling operations.

- Safety and Efficiency: Modern shredder designs include safety features and control systems that protect workers and ensure efficient operation.

Car radiator shredders play a crucial role in the recycling industry by breaking down complex items into their component materials, making the recycling process more efficient and environmentally friendly.

Factors Influencing Car Radiator Shredders Price

-

Car Radiator Shredders Configuration

- ประเภทใบมีดและวัสดุ: เครื่องทําลายเอกสารที่แตกต่างกันใช้การกําหนดค่าใบมีดและวัสดุต่างๆ (เช่น, เหล็กกล้า) เพื่อความทนทานและประสิทธิภาพ.

- มอเตอร์ไฟฟ้า: ช่วงตั้งแต่ 50 HP ขึ้นไป 500 HP ขึ้นอยู่กับขนาดและความจุของเครื่องทําลายเอกสาร.

- ยี่ห้อและผู้ผลิต: แบรนด์ที่มีชื่อเสียงซึ่งมีประวัติความน่าเชื่อถือและประสิทธิภาพจะส่งผลกระทบอย่างมากต่อต้นทุน.

- กำหนด เอง: เครื่องจักรที่ปรับให้เหมาะกับการใช้งานเฉพาะหรือที่มีการกําหนดค่าพิเศษอาจมีราคาแพงกว่า.

-

Additional costs

- การขนส่งและการขนส่ง: ขึ้นอยู่กับสถานที่, การขนส่งเครื่องทําลายยางขนาดใหญ่สามารถเพิ่มต้นทุนทั้งหมดได้หลายพันดอลลาร์.

- การติดตั้งและการตั้งค่า: การติดตั้งและการตั้งค่าอย่างมืออาชีพจะเป็นค่าใช้จ่าย.

- การบํารุงรักษาและอะไหล่: การบํารุงรักษาอย่างต่อเนื่องและค่าใช้จ่ายของชิ้นส่วนอะไหล่ควรนํามาพิจารณาในงบประมาณโดยรวม.

FAQs about Car Radiator Shredders

Q:What are the benefits of Car Radiator Shredders?

A: ช่วยให้สามารถสกัดโลหะมีค่า เช่น ทองแดง, อลูมิเนียม; ลดต้นทุนในการขนส่งและการเก็บรักษา.

Q: What is the price of a car radiator shredder ?

A: The price of a car radiator shredder can vary significantly depending on its size, ความสามารถ, ขนาดการปล่อย, ยี่ห้อมอเตอร์และอื่น ๆ.

บทสรุป

Car radiator shredders are essential for resource recovery, ช่วยลดของเสียและรีไซเคิลวัสดุได้อย่างมีประสิทธิภาพ. When purchasing a radiator shredder, it’s important to consider factors such as the type and volume of material we need to process, ความจุและคุณสมบัติของเครื่อง, การสนับสนุนหลังการขาย, และการรับประกัน.

เครื่องทําลายเอกสาร Wali

เครื่องทําลายเอกสาร Wali