What is the shredder category?

Table of Content

- Shredder Category

- Single Shaft Shredder

- Dual Shaft Shredder (Twin Shaft Shredder)

- Quad Shaft Shredder (Four Shaft Shredder)

- Key Considerations When Choosing a Shredder

- FAQs about Industrial Shredders

- Conclusion

Shredder Category

Shredders can be categorized based on their shaft configuration, which determines how they process materials. The following are the types of shredders, including single shaft, dual shaft, and more.

Single Shaft Shredder

Description:

- A single shaft shredder has a rotor (shaft) with cutting blades that shred the material against a counter blade.

- Material is fed into the shredder and pushed towards the rotor by a hydraulic or mechanical pusher system.

Features:

- Suitable for shredding a variety of materials including plastics, wood, rubber, and paper.

- Offers precise control over particle size with screen options.

- Generally operates at lower speeds, which reduces noise and dust.

Applications:

- Ideal for recycling processes, reducing the size of bulky materials, and preparing materials for further processing.

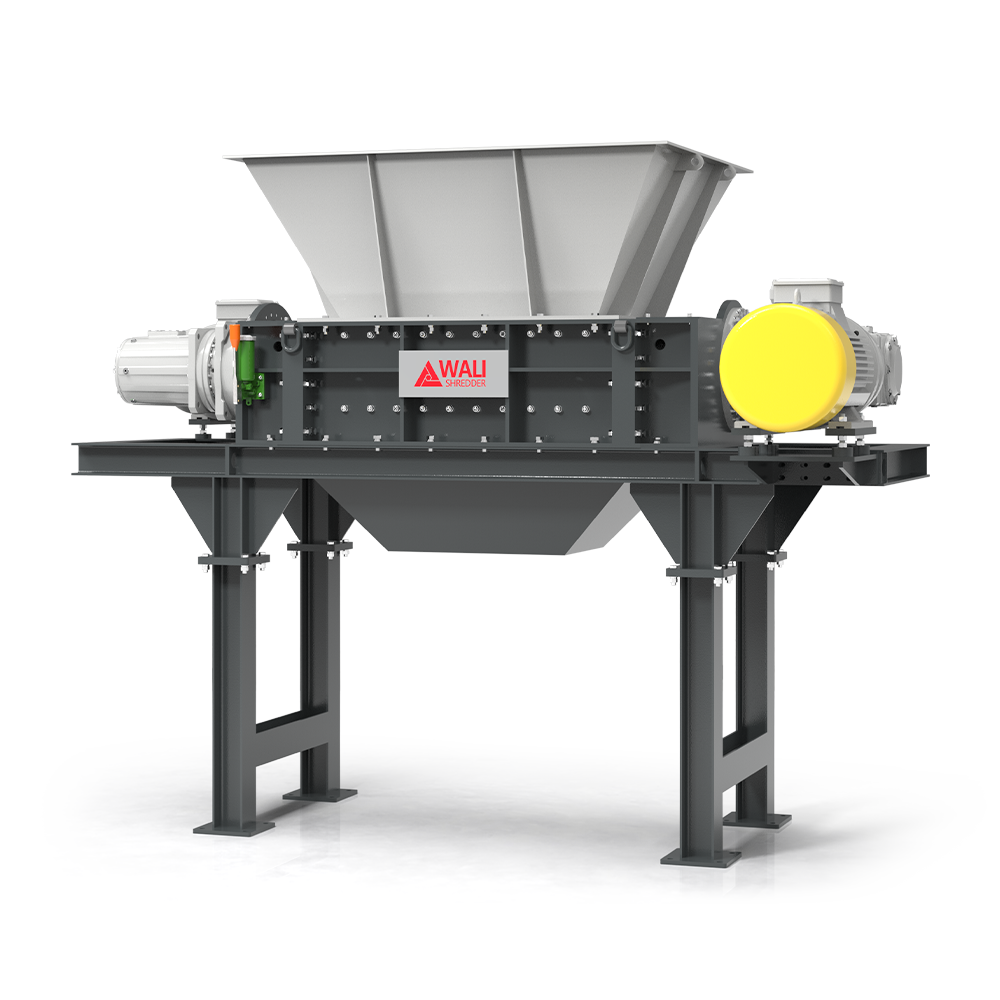

Dual Shaft Shredder (Twin Shaft Shredder)

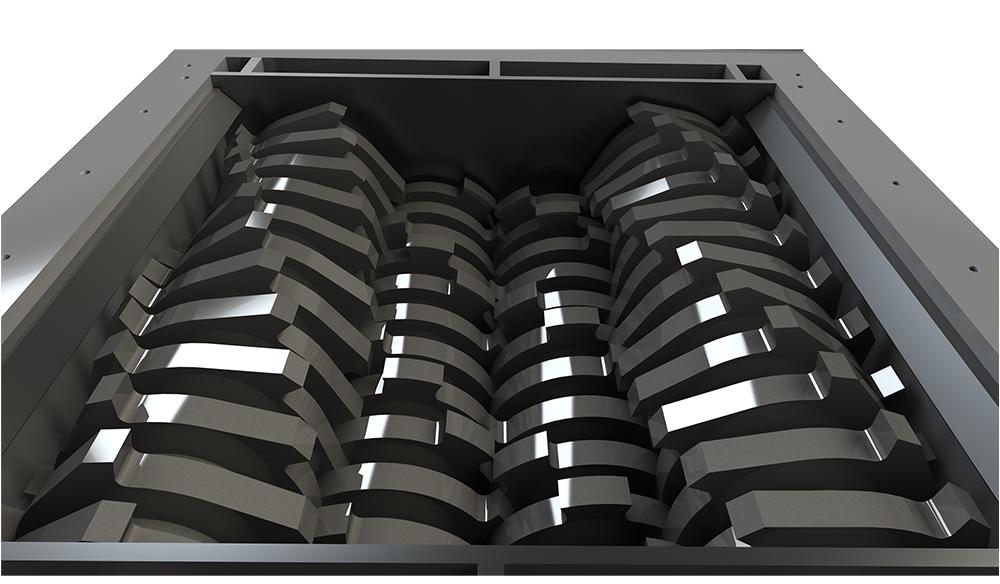

Description:

- Dual shaft shredders have two parallel shafts with cutting blades that rotate inward to pull material in and shred it.

- Material is shredded between the shafts and the blades, which intermesh.

Features:

- High torque and low speed operation.

- Capable of handling larger and tougher materials like metals, tires, solid waste and bulky waste.

- Can operate with minimal maintenance.

Applications:

- Suitable for heavy-duty applications such as waste processing, recycling of metals, tires, sofa, mattress, furniture and other tough materials.

Quad Shaft Shredder (Four Shaft Shredder)

Description:

- Quad shaft shredders have four shafts with multiple cutting disks that work together to shred material into smaller pieces.

- The material is processed through two stages of cutting, first with the primary shafts and then with secondary shafts.

Features:

- Provides finer and more uniform particle size.

- High throughput capacity.

- Often used for applications requiring consistent, small particle size.

Applications:

- Commonly used for shredding e-waste, plastics, and complex waste streams that require thorough processing.

Key Considerations When Choosing a Shredder

Material Type:

- Determine the primary materials you need to shred (e.g., plastic, metal, wood, e-waste).

Shredding Capacity:

- Assess the volume of material you need to process and choose a shredder with the appropriate capacity.

Desired Output Size:

- Consider the required particle size for your application and select a shredder that can achieve it.

Operational Environment:

- Ensure the shredder can operate efficiently in your specific environment, whether it’s an industrial setting or part of a production line.

Maintenance Requirements:

- Evaluate the maintenance needs of the shredder to ensure it aligns with your operational capabilities and downtime tolerance.

FAQs about Shredder Category

Q1: How to categorize shredder?

A1: According to the structure, the shredder can be divided into these categories. we can also get other categories based on the application of the shredder(details can refer to the previous chapter).

Conclusion

Understanding these different categories of shredders and their specific features will help us select the right type for our material processing needs, ensuring efficiency and effectiveness in our shredding operations.

Wali Shredder

Wali Shredder