Что такое измельчитель холодильника?

Что такое измельчитель холодильника?

Содержание

- Refrigerator Shredders

- The types of Refrigerator Shredders

- How Refrigerator Shredders Work

- Key Components of a Refrigerator Shredder

- Функции безопасности

- Benefits of Refrigerator Shredders

- Factors InfluencingA Refrigerator Shredder Price

- How to Choosing the Right Shredder

- FAQs about Refrigerator Shredders

- Заключение

Refrigerator Shredders

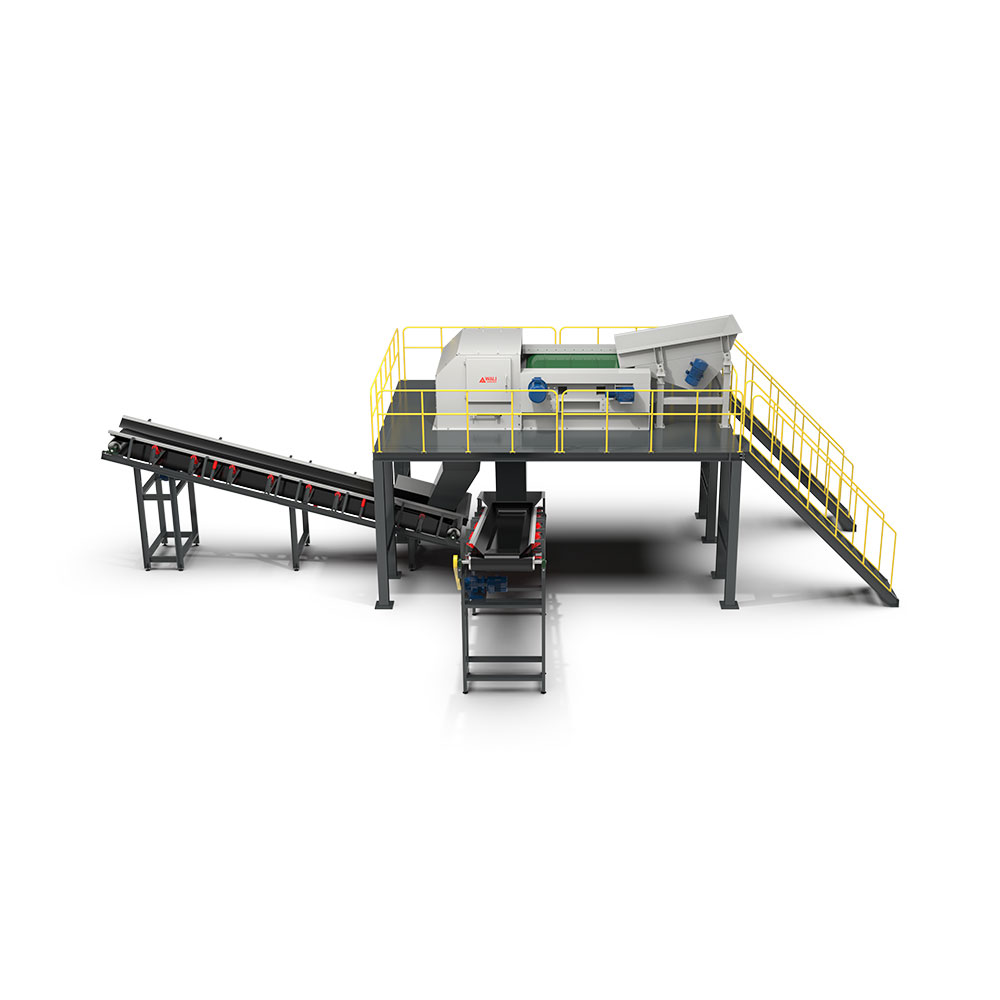

A refrigerator shredder is a specialized machine used to break down and recycle old or unused refrigerators. These shredders are part of a broader recycling process aimed at recovering valuable materials and reducing waste.

The types of Refrigerator Shredders

Refrigerator shredders come in various types, each designed to handle specific aspects of the shredding and recycling process. Here are the primary types of refrigerator shredders and their characteristics:

-

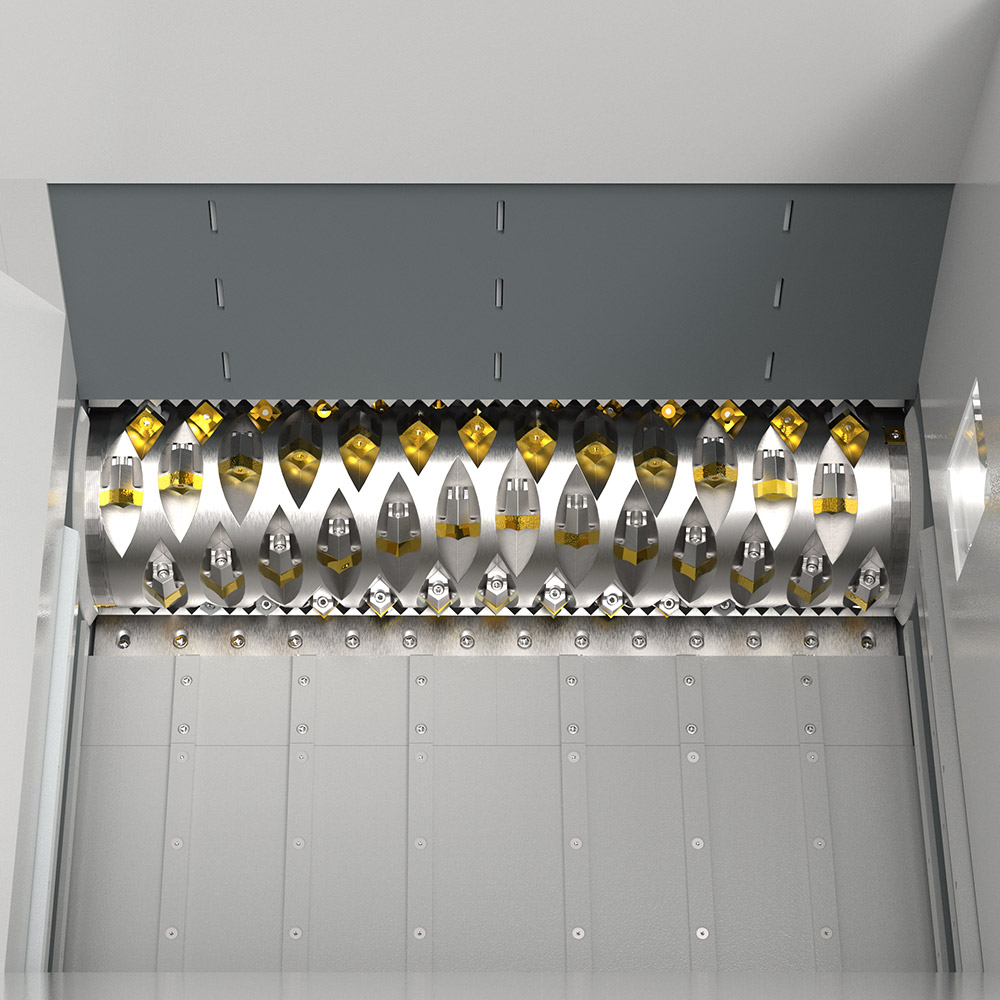

Single-Shaft Shredders

- Description: These shredders have a single rotating shaft with cutting blades.

- Usage: Suitable for smaller operations where refrigerators are fed manually. They are effective for primary size reduction.

- Advantages: Simple design, relatively lower cost, and easy maintenance.

-

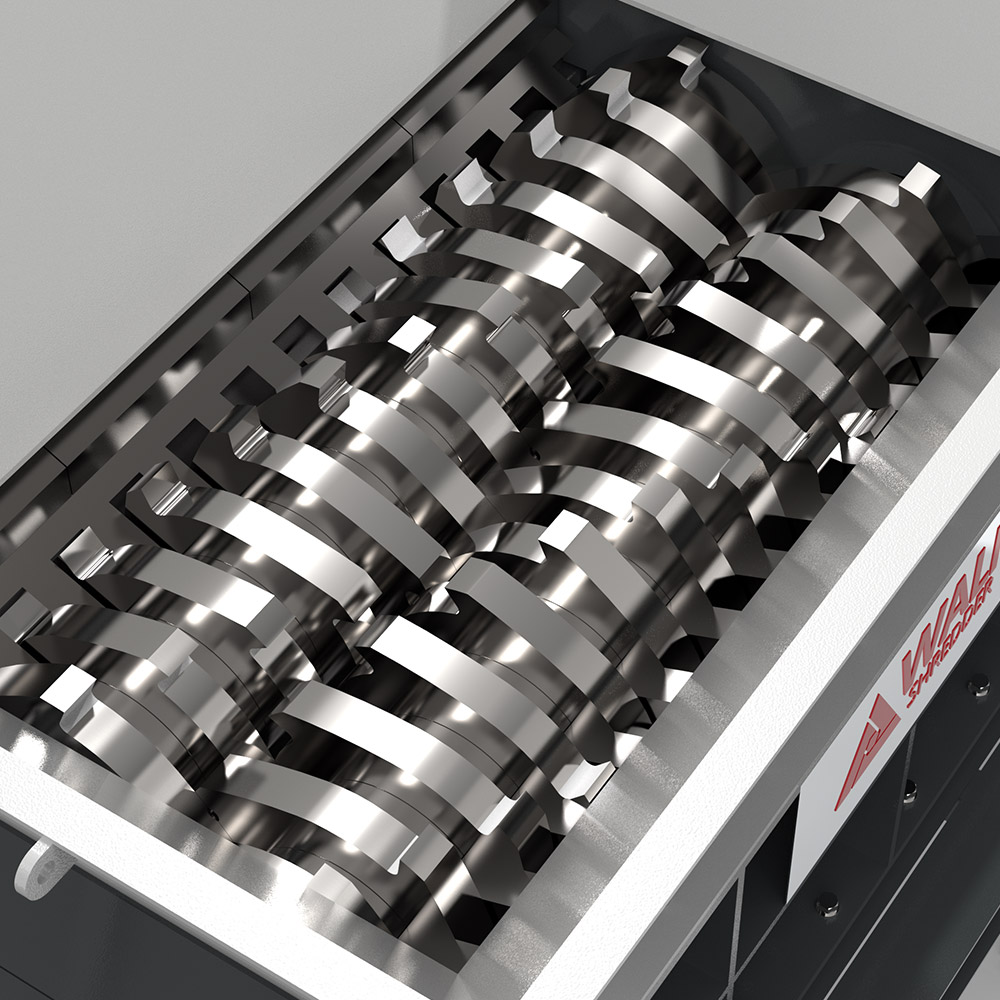

Dual-Shaft Shredders

- Description: Equipped with two rotating shafts with cutting blades that work together to shred materials.

- Usage: Ideal for more demanding applications and larger volumes. They provide more thorough shredding compared to single-shaft shredders.

- Advantages: Greater shredding power and efficiency, better handling of large or bulky items.

-

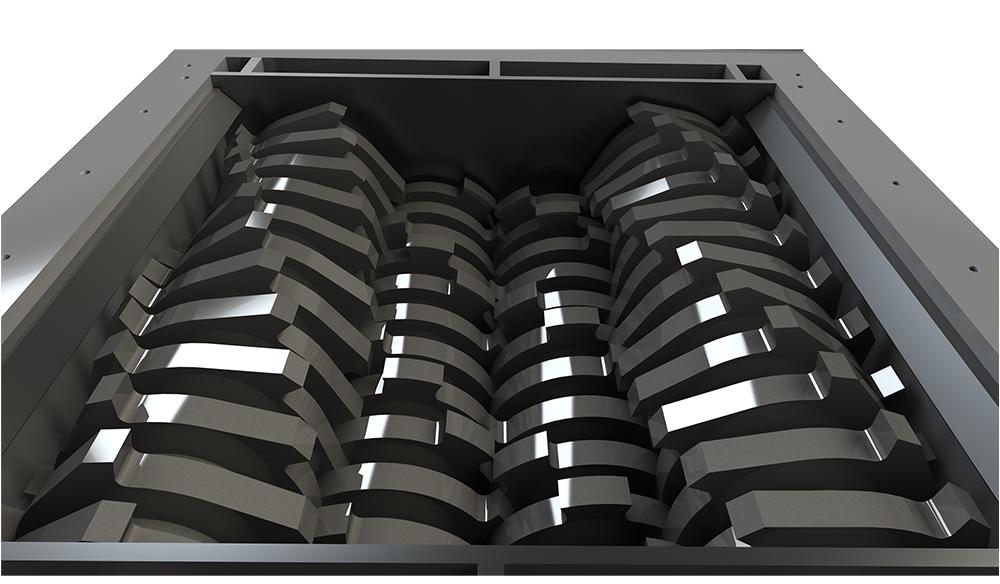

Four-Shaft Shredders

- Description: These shredders have four intermeshing shafts with cutting blades, providing additional shredding stages.

- Usage: Used for comprehensive shredding and size reduction, ensuring materials are broken down into very small pieces.

- Advantages: Highly efficient in producing uniformly small output, capable of handling complex and tough materials.

-

Granulators

- Description: Machines that further refine shredded materials into smaller granules.

- Usage: Often used after initial shredding to achieve finer granulation of the material, making it easier to separate and recycle.

- Advantages: Produces very fine and consistent particle sizes, ideal for separating mixed materials.

-

Hammer Mills

- Description: Use hammers attached to a rotating shaft to crush and shred materials.

- Usage: Suitable for breaking down tough materials like metals within refrigerators. They can handle high volumes and provide significant size reduction.

- Advantages: Powerful and efficient, capable of handling a variety of materials, especially metals.

How Refrigerator Shredders Work

-

Preparation:

- Removal of Hazardous Materials: Before shredding, refrigerators must be properly drained of any harmful substances, such as refrigerants (like Freon) and oils, which are environmentally hazardous.

-

Кормление:

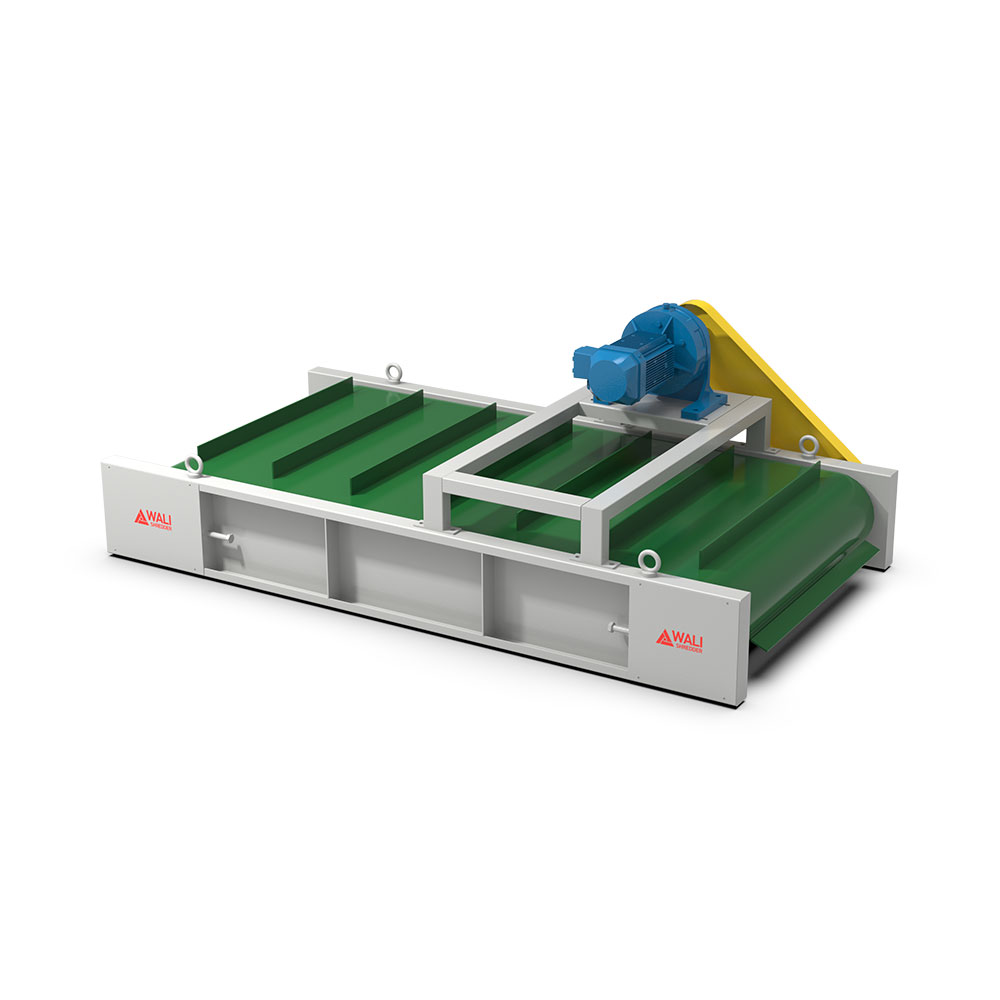

- Manual or Conveyor Feeding: The refrigerators are fed into the shredder either manually or via a conveyor belt system in larger operations.

-

Первичное измельчение:

- Rotating Blades/Cutters: The shredder uses robust, rotating blades or cutters to break the refrigerator into smaller, manageable pieces.

-

Initial Separation:

- Discharge Chute: The shredded material is discharged onto a conveyor belt or directly into a separation system.

-

Separation Systems:

- Магнитная сепарация: Powerful magnets remove ferrous metals (like steel) from the shredded material.

- Air Separation: Airflow is used to separate lighter materials (like plastics and insulation) from heavier metals.

- Vibration Separation: Vibrating screens sort materials based on size and density.

-

Вторичное измельчение (Optional):

- Further Refinement: Some systems may include a secondary shredding stage to ensure finer granulation and more thorough separation.

-

Final Separation and Purification:

- Eddy Current Separator: This device separates non-ferrous metals (such as aluminum and copper) from other materials using a magnetic field.

- Density Separator: Materials are further separated based on density, often using water or air.

-

Collection and Storage:

- Separated Materials: The separated materials (metals, Пластмасс, foam insulation) are collected in different bins or conveyors.

- Storage: The materials are stored until they are transported to recycling facilities for further processing.

Key Components of a Refrigerator Shredder

- Blades/Cutters: Made from high-strength, wear-resistant materials to handle tough materials.

- Motors and Drives: Provide the necessary power for shredding.

- Conveyor Belts: Facilitate the movement of refrigerators into the shredder and the transportation of shredded materials.

- Системы управления: Monitor and adjust the operation for safety and efficiency.

- Dust and Noise Control: Manage emissions and reduce noise for a safer working environment.

Функции безопасности

- Emergency Stop Buttons: Allow immediate shutdown in case of an emergency.

- Защитные ограждения: Protect operators from moving parts.

- Sensors: Detect blockages or jams and automatically shut down the machine to prevent damage and injury.

Benefits of Refrigerator Shredders

- Efficient Recycling: Maximizes the recovery of valuable materials, reducing waste.

- Environmental Protection: Ensures proper disposal of hazardous substances and reduces landfill use.

- Economic Benefits: Recovers valuable metals and other materials that can be sold or reused, offsetting recycling costs.

- Safety and Efficiency: Modern designs include safety features and control systems that protect workers and ensure efficient operation.

Refrigerator shredders are essential for the effective recycling of refrigerators, helping to recover valuable resources and minimize environmental impact.

Factors Influencing A Refrigerator Shredder Price

-

A Refrigerator Shredder Configuration

- Тип и материал лезвия: В различных измельчителях используются различные конфигурации лезвий и материалы (например., сталь) Для долговечности и эффективности.

- Мощность двигателя: Варьируется от 50 HP до более чем 500 Мощность в зависимости от размера и производительности измельчителя.

- Бренд и производитель: Авторитетные бренды с историей надежности и производительности существенно повлияют на его стоимость.

- Настройка: Машины, адаптированные для конкретных областей применения или со специальными конфигурациями, могут быть более дорогими.

-

Дополнительные расходы

- Доставка и транспортировка: В зависимости от местоположения, Транспортировка большого измельчителя шин может добавить несколько тысяч долларов к общей стоимости.

- Установка и настройка: Профессиональная установка и настройка будут затратами.

- Техническое обслуживание и запасные части: Текущее техническое обслуживание и стоимость запасных частей должны быть учтены в общем бюджете.

How to Choosing the Right Shredder

When selecting a refrigerator shredder, consider the following factors:

- Volume: The amount of material to be processed.

- Material Composition: Types of materials (металл, plastic, insulation) present in the refrigerators.

- End Goals: Desired size and purity of the output material.

- Operational Scale: Size of the recycling operation and available space.

- Budget: Cost considerations, including initial investment and ongoing maintenance.

Each type of shredder offers unique benefits and is suited to different aspects of the recycling process, helping to maximize material recovery and minimize environmental impact.

FAQs about Refrigerator Shredders

Q:What are the benefits of refrigerator shredders?

A: Enables the extraction of valuable metals like copper, aluminum; снижение затрат на транспортировку и хранение.

Q: What is the price of a refrigerator shredder?

A: The price of a refrigerator shredder can vary significantly depending on its size, способность, Размер разгрузки, марки автомобилей и так далее.

Заключение

Refrigerator shredders are essential for resource recovery, helping to reduce waste and recycle materials efficiently. When purchasing a refrigerator shredder, it’s important to consider factors such as the volume, the machine’s capacity and features, after-sales support, and warranty.

Шредер Страж

Шредер Страж