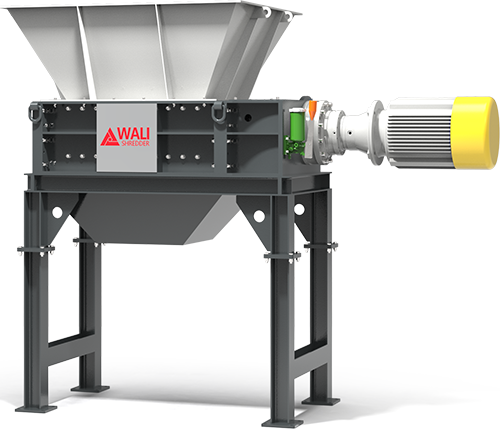

WLS Double shaft shredder

Throughput:0.5-3T/H

Discharge size:15-200mm

Product introduction

Double shaft shredder – WLS

WLS is a two shaft shearing shredder with two rotors and one motor, featuring low speed and high torque, the motor power range of 5.5~30 kw, making it more energy-efficient.

This specialised design specific to shred and tear a wide range of difficult-to-crush and solid materials with a small throughput capacity of 300kg/h-3000kg/h, such as metal barrels, carton boxes, kitchen waste, electrical waste, etc.

Compared with a single shaft shredder, it is not equipped with a sieve, which allows materials to be discharged directly after input.

Also, it can work as a stand-alone machine or be used in recycling production lines.

Considering the small processing capacity for solid waste and smaller footprint, WLS is a good choice.

The highlights of the WLS-shredder

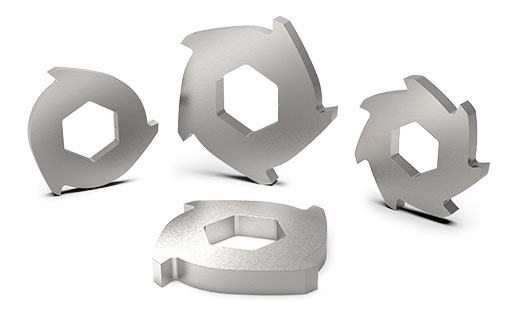

01.Superior alloy steel

02.Anti-winding fixed blades

This design effectively prevents matrials from winding around the blade during processing, minimizing downtime caused by blockages and ensuring continuous operation of equipment.

03.Quadruple combination bearing seal

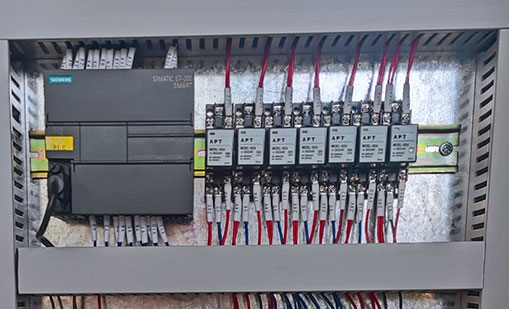

04.PLC controlling system

05.Auto-reverse

06.Low operation and maintenance cost

What Waste Can We Shred?

+ Kitchen waste: Fruit and vegetable waste, kitchen waste, farmer’s market waste, repasting waste, etc.

+ Domestic waste: (Does not contain high hardness materials such as iron,stone, ceramics, etc.)

+ Plastic waste: Plastic bottles, plastic jugs, plastic buckets, plastic baskets,etc.

+ Electronic waste: Old hard disk, PCB boards, keyboards, mice, mobile phones,CDs, etc.

+ Metal waste: Iron filings, cans, paint buckets, thin metal materials, etc.

+ Medical waste: Syringe waste, pharmaceutical waste, small medical devices, latex material waste, discarded masks, etc.

+ Paper products: Used cartons, cardboard, newspapers, books, documents, brochures, wrapping paper, etc.

+ Industrial waste: Old clothes, leather, textile scraps, carpet factory waste fabric, general industial waste, etc.

Crushing effect

Crushing cases

Which model suits your needs?

| Model | Equipment dimension | Crushing chamber dimension | Cutter diameter×thickness | Cutter quantity | Rotate speed | Motor power | Equipment N.W. | Capacity |

|---|---|---|---|---|---|---|---|---|

| Unit | L×W×H mm | mm | mm | Pcs | r/min | Kw | Kg | Kg |

| S350 | 1320*800*1800 | 450*350 | φ235*10/20 | 34/18 | 27 | 5.5/7.5 | approx600 | approx 300-800 |

| S505 | 2240*1050*2020 | 550*500 | φ280*20/30 | 30/20 | 18 | 15/18.5 | approx1200 | approx500-1500 |

| S608 | 2500*1120*2230 | 640*800 | φ300*20/30 | 42/26 | 15-20 | 22 | approx1800 | approx1000-2500 |

| S710 | 2510*1865*2550 | 690*1000 | φ330*30 | 34 | 15-20 | 30 | approx2200 | approx1500-3000 |

| The above shredder is our standard configuration. For different raw materials to be shredded, the configuration might be different. Please feel free to contact us for detailed information or special request. | ||||||||

Why Choose Us?

Outlined below are some key reasons to choose us.

- Recycling Equipment Manufacturer

- Supprt Customized Services

- Competitive Price

- One Stop Solid Waste Recycling Solution

- Strict Quality Control Process

- Reliable Delivery

- Professional R&D Design

- Perfect After-sales Service

Our Manufacturing Plant

Our factory is located in Maanshan, China. Maanshan was the first steel production base in China, supplying 90% of the country’s blades.

As a shredder manufacturer, we have a complete raw material supply chain and cost advantages.

We have a professional technical team and rich project experience, as well as can provide high quality products and one-stop recycling solutions for various solid waste projects.

FAQs

Got Questions? We’ve Got Answers

Are you a factory or a trading company?

We are a professional equipment manufacturer with special sales and engineering teams. We have over 20 years of solid waste recycling project experience since our establishment in 2004.

Where is your company?

Located in Maanshan, Anhui Province, our company is only a 30-minute drive from Nanjing Lukou Airport. If you plan to visit us, we’ll pick you up at the airport.

How to ensure that the machine I ordered is suitable for me?

Before placing an order, our sales team will conduct detailed and in-depth communication with you to determine your specific requirements. We then recommend machine configurations based on your needs, ensuring that you buy the best machine for your business. We insist on providing the most competitive products when meeting the needs of our customers.

Do you support OEM and ODM?

Yes, we support OEM and ODM, which includes customizing the appearance, color, configuration, even produce the complete machine according to your drawings and requirements. payment options.

MOQ

We accept a minimum quantity of one and can customize it according to your requirements.

How do you ensure the quality of your machines?

We employ a variety of large equipment, such as tempering furnaces and shot blasting machines, to ensure the strength and stability of the frame. To guarantee machine accuracy, we use five-axis machining centers and floor boring and milling equipment. Additionally, our machine processing, assembly, and quality inspection follow standardized processes, ensuring product quality is controlled throughout the production process.

How long is the delivery time?

Typically, we deliver goods within 30 days. If the machine is a customized product, it may take longer. However, the delivery time for such machines will not exceed 50 days.

What are your terms of payment?

We generally accept T/T and L/C payments, with a 30% deposit and 70% payment before delivery.

What kind of packing do you use for your machines?

Due to the large volume of the equipment, we usually wrap the whole machine with plastic wrap, and wrap the foam around the corner of the machine, and then put the machine into the container and fix it with steel wire to prevent the machine from shifting or colliding during transportation. In addition, for a single piece of equipment, we can customize wooden boxes and pallets for customers to unload and transport.

What is the warranty period of your machine?

Our warranty period for conventional machines is one year, not including the wear parts. Please confirm the warranty period with our sales team in advance. During the warranty period, we offer free replacement parts.

How does your company provide after-sales service?

We offer remote assistance from our mechanical engineers to resolve minor issues that may arise during the use of our machines. This includes one-to-one guidance, with the option of sending text instructions or videos to help you solve the problem. If any parts need to be replaced during the warranty period, we will provide them free of charge. However, you may also purchase the parts locally to save time. If remote guidance is insufficient to address more serious problems, we will arrange for engineers to provide on-site service. In regions where we have agents, we will contact them directly to provide service.

Does your company provide training?

We welcome you to arrange for relevant personnel to come to our company for on-site study, and we will provide specialized one-to-one guidance. However, if it is inconvenient for you to visit our company, we can also provide remote training options.

Will your company provide relevant paper materials?

Certainly. Along with machine delivery, we typically provide various manuals, operating instructions, precautions, circuit diagrams, hydraulic diagrams, and other materials.

What shipping methods do you support?

Our factory supports EXW, FOB, CRF, door to door, etc. We have professional freight forwarders who can arrange the transportation of goods.

Contact Us

WALI Recovering And Recycling Valuable Resources Back Into The Supply Chain.

Wali Shredder

Wali Shredder