Tel: +86-177 3033 8505 E-mail: [email protected]

Hammers Mills/

- Home

- Products

- Hammers Mills

- Alligator shear

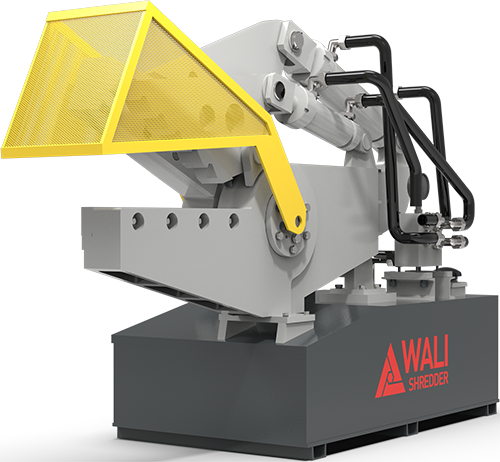

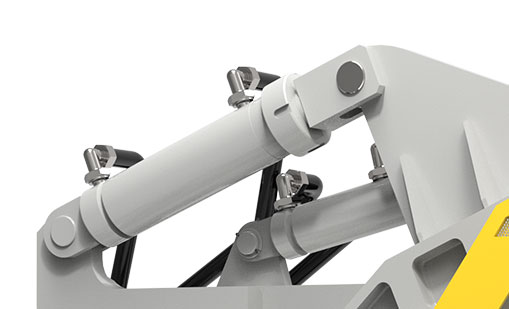

WLAS Alligator shear

Throughput:300-2000kg/H

Shear thickness:10-60mm

Product introduction

Alligator shear also known as crocodile or lever shears helps in cutting a large variety of metal scrap. The scrap like round, channel, bar, TMT can be sheared easily with hydraulic shearing machine. WALI scrap cutting machine help facilities prepare scrap for shredding, add value to scrap and improve the quality of processed scrap. At WALI, we build two types of alligator shearing machines – mechanical and hydraulic operated shearing machine. Our alligator shears possess a cutting capacity of up to 85 mm. We build shears of different capacities to fulfil the different requirements of customers, while maintaining consistency in terms of innovation, high quality of raw materials and finished products, and global standards. We build both manual and automatic alligator shears which are easy as well as safe to operate, and are globally lauded for their premium quality and standards.Alligator shears are simple to operate and feature fast cycle times, while maintaining a high cutting force for tough scrap material such as steel, bar, wire, cable, plates, tubes and other mixed metal products.

The highlights of the WLAS-Alligator Shear

Powerful Cutting Ability

Versatile Cutting Targets: Capable of handling various metal materials, from thin sheets to heavy rebar.High Cutting Precision: Hydraulic drive provides stable cutting force, ensuring clean cut edges.High Productivity: Suitable for large-scale metal scrap processing, with high efficiency and output.

Cutting Power

-

Minimal Space Occupation: Compact design, ideal for installation in confined workspaces. -

Easy to Move and Install: Lightweight structure, simple to install and disassemble, allowing for easy relocation between job sites. -

Simple Design: Reduces unnecessary complex components, lowering maintenance difficulty and costs.

Easy Operation

- User-friendly Control Panel: Intuitive control interface, easy to operate, with a short learning curve.

- High Automation: Can be set for semi-automatic or fully automatic operation modes with simple settings.

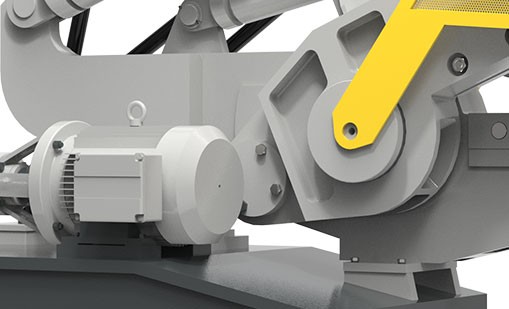

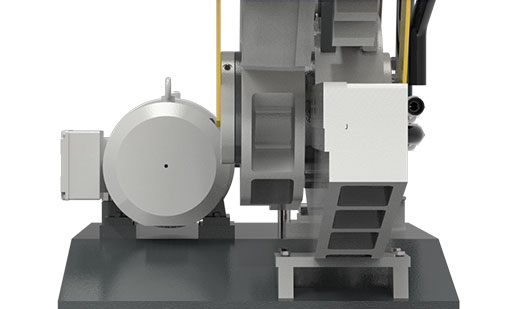

Efficient and Energy-Saving

- Low Energy Consumption: Optimized hydraulic system design reduces power consumption, saving operational costs.

- High Energy Conversion Efficiency: Hydraulic power provides efficient energy transmission, minimizing energy waste.

High Safety

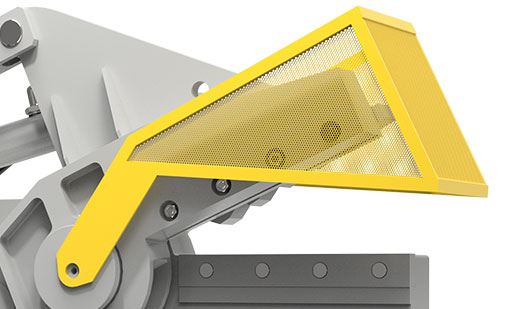

- Multiple Safety Devices: Equipped with protective covers, emergency stop buttons, and other features to ensure operational safety.

- Automatic Fault Detection: The equipment has self-diagnosis capabilities to detect and report faults promptly, preventing accidents.

Durability

- High-Strength Materials: Made of high-strength steel and wear-resistant components, extending the equipment’s service life.

- Corrosion-Resistant Design: Key components are specially treated for strong corrosion resistance, suitable for various harsh working environments.

What types of scrap metal can be processed with alligator shears?

Alligator shears are highly versatile and can process many scrap metals, including steel, copper, aluminum, brass, etc. Their adaptability makes them suitable for various recycling applications.

What types of scrap metal can be processed with alligator shears?

Alligator shears are highly versatile and can process many scrap metals, including steel, copper, aluminum, brass, etc. Their adaptability makes them suitable for various recycling applications.

Why Choose Us?

Outlined below are some key reasons to choose us.

- Competitive Price

- Maintenance friendly

- Technical Support

- Expert Solutions

- Short Lead Time

- Various options

- Quality Control

- Expandable by customer specification

Our Manufacturing Plant

As a manufacturing and trading integrated company, we own our factory and strictly control every stage of the production process.

Are you a factory or a trading company?

We are a manufacturer. We have over 20 years of production experience since our establishment in 2004.

Where is your company?

Located in Maanshan, Anhui Province, our company is only a 30-minute drive from Nanjing Lukou Airport. If you plan to visit us, we can arrange a special bus to pick you up from the airport.

How long does it take to deliver the machine?

Typically, we deliver goods within 30 days. If the machine is a non-standard customized product, it may take longer. However, the delivery time for such machines will not exceed 50 days.

What kind of payment do you accept?

We generally accept T/T and L/C payments, with a 30% deposit and 70% payment before delivery. However, for special customers, we can offer better payment options.

What is the warranty period of your machine?

Our warranty period for conventional machines is one year, while for special non-standard machines, we may offer a 2-3 year warranty. Please confirm the warranty period with our sales team in advance. During the warranty period, we offer free replacement parts.

Do you accept OEM customization?

Yes, we accept OEM customization, which includes customizing the appearance, color, configuration, and more. However, please note that the price for customized products may be slightly higher. Please contact our business team for more details.

What is the minimum order quantity of your machines?

We accept a minimum quantity of one and can customize it via OEM to meet your specific needs.

How do you ensure the quality of your machines?

We employ a variety of large equipment, such as tempering furnaces and shot blasting machines, to ensure the strength and stability of the frame. To guarantee machine accuracy, we use five-axis machining centers and floor boring and milling equipment. Additionally, our machine processing, assembly, and quality inspection follow standardized processes, ensuring product quality is controlled throughout the production process.

What kind of packing do you use for your machines?

Due to the large size of our equipment, we typically load them directly into containers and secure them using steel wires to prevent damage during transportation by sea. To ensure the machines remain intact, we take extra care to prevent them from hitting the inside of the container during the ship’s movement. Furthermore, we ensure that no other items are placed in the container with your ordered machine.

How does your company provide after-sales service?

We offer remote assistance from our mechanical engineers to resolve minor issues that may arise during the use of our machines. This includes one-to-one guidance, with the option of sending text instructions or videos to help you solve the problem. If any parts need to be replaced during the warranty period, we will provide them free of charge. However, you may also purchase the parts locally to save time. If remote guidance is insufficient to address more serious problems, we will arrange for engineers to provide on-site service. In regions where we have agents, we will contact them directly to provide service.

Does your company provide training?

We welcome you to arrange for relevant personnel to come to our company for on-site study, and we will provide specialized one-to-one guidance. However, if it is inconvenient for you to visit our company, we can also provide remote training options.

How do you charge the ocean freight?

Ocean freight charges are typically determined by the freight forwarder. You have the option of using our freight forwarder to arrange delivery or selecting your own freight forwarder.

Will your company provide relevant paper materials?

Certainly. Along with machine delivery, we typically provide various manuals, operating instructions, precautions, circuit diagrams, hydraulic diagrams, and other materials.

How to ensure that the machine I ordered is suitable for me?

Before placing an order, our sales team engages in detailed and in-depth communication with you to determine your specific requirements. We then recommend a machine configuration tailored to your needs, ensuring that you purchase the most suitable machine for your business. Our priority is not to recommend more expensive machines to generate sales, as expensive machines may not be the most suitable for your needs.

Contact Us

WALI Recovering And Recycling Valuable Resources Back Into The Supply Chain.

Wali Shredder

Wali Shredder