What is a plastic shredder?

Table of Content

- Plastic Shredders

- Key Components of a Plastic Shredder

- Types of Plastic Shredders and Their Operation

- Uses of Plastic Shredders

- Factors to Consider When Purchasing a Plastic Shredder

- FAQs about Plastic Shredders

- Conclusion

Plastic Shredders

A plastic shredder is a machine used to reduce plastic materials into smaller pieces for easier recycling, reuse, or disposal. These machines are essential in plastic recycling processes and come in various types and sizes, each designed to handle different kinds of plastic waste.

Key Components of a Plastic Shredder:

- Cutting Mechanism: Usually consists of sharp blades or knives that slice through plastic.

- Motor: Powers the cutting mechanism.

- Hopper: The intake area where plastic waste is fed into the shredder.

- Discharge Area: Where shredded plastic exits the machine, often into a bin or conveyor system.

- High Capacity: Capable of processing large volumes of plastic waste.

- Durable Construction: Made with heavy-duty materials to withstand continuous operation.

- Versatile Blades: Equipped with strong, sharp blades that can handle a variety of plastic types.

- Automated Controls: Often include advanced control systems for easy operation and monitoring.

Types of Plastic Shredders and Their Operation

-

Single-Shaft Shredder:

- Operation: Features a single rotor with cutting blades that rotates inside the shredder. The plastic material is fed into the machine through a hopper and is shredded against a stationary blade.

- Advantages: Suitable for processing a variety of plastic materials, including large, bulky items. Provides consistent particle size.

-

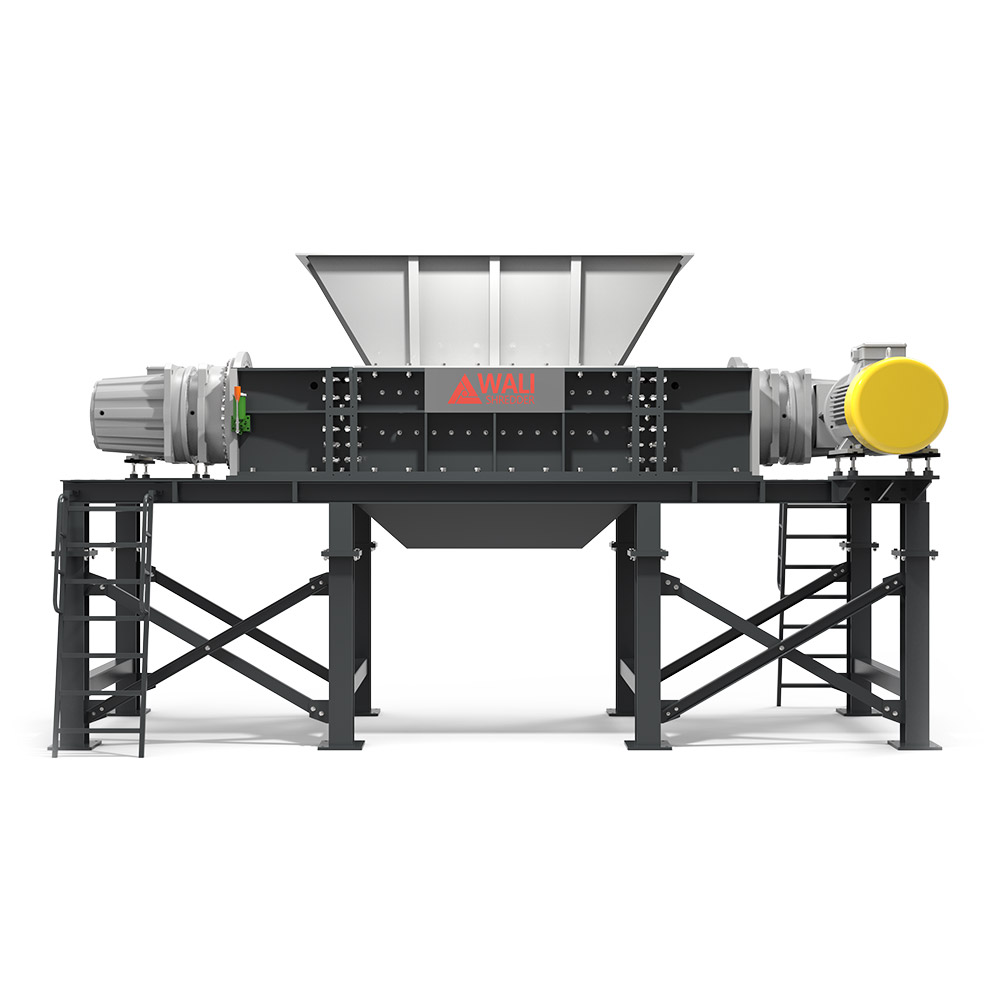

Double-Shaft Shredder:

- Operation: Uses two interlocking, counter-rotating shafts with cutting blades. Plastic material is fed into the machine and is shredded by the rotating blades.

- Advantages: More powerful and capable of handling tougher, more resilient plastic materials. Produces larger, more irregularly sized particles.

Uses of Plastic Shredders:

- Recycling: Breaks down plastic waste for reprocessing into new products.

- Waste Management: Reduces the volume of plastic waste for easier handling and disposal.

- Industrial: Prepares plastic materials for further processing in manufacturing.

Factors to Consider When Purchasing a Plastic Shredder

- Material Type: Ensure the shredder can handle the specific types of plastic we need to process.

- Capacity: Consider the volume of plastic you need to shred regularly.

- Particle Size: Determine the desired output size of the shredded plastic.

- Power Requirements: Ensure the shredder meets our facility’s power availability.

- Maintenance and Support: Look for manufacturers or suppliers that offer robust customer support and maintenance services.

- Customization: Some manufacturers offer customizable options to fit specific needs.

Factors Influencing Plastic Shredders Price

1.Plastic Shredders Configuration

- Blade Type and Material: Different shredders use various blade configurations and materials (e.g., steel) for durability and efficiency.

- Motor Power: Ranges from 50 HP to over 500 HP depending on the shredder’s size and capacity.

- Brand and Manufacturer: Reputable brands with a history of reliability and performance will significantly impact its cost.

- Customization: Machines tailored for specific applications or with special configurations may be more expensive.

2.Additional Costs

- Shipping and Transportation: Depending on the location, transporting a large tire shredder can add several thousand dollars to the total cost.

- Installation and Setup: Professional installation and setup will be an expense.

- Maintenance and Spare Parts: Ongoing maintenance and the cost of replacement parts should be factored into the overall budget.

FAQs about Plastic Shredders

Q:What are the benefits of Plastic Shredders ?

A: Facilitating resource recovery, reducing costs in transportation and storage.

Q: What is the price of a Plastic Shredder ?

A: The price of a Plastic shredder can vary significantly depending on its size, capacity, discharge size, motor brands and so on.

Conclusion

Plastic Shredders are robust machines designed for high-volume processing of plastic waste. They are commonly used in recycling facilities, manufacturing plants, and waste management centers to efficiently reduce plastic materials into smaller, manageable pieces for further processing or disposal. When choosing a plastic shredder, it’s essential to consider factors such as the type of materials, the volume of material, discharge size, installation space and budget.

Wali Shredder

Wali Shredder