What is a car shredder?

Table of Content

- Car Shredders

- Key Features of Car shredders

- How does Car Shredder Work?

- Factors Influencing Car Shredders Price

- FAQs about Car Shredders

- Conclusion

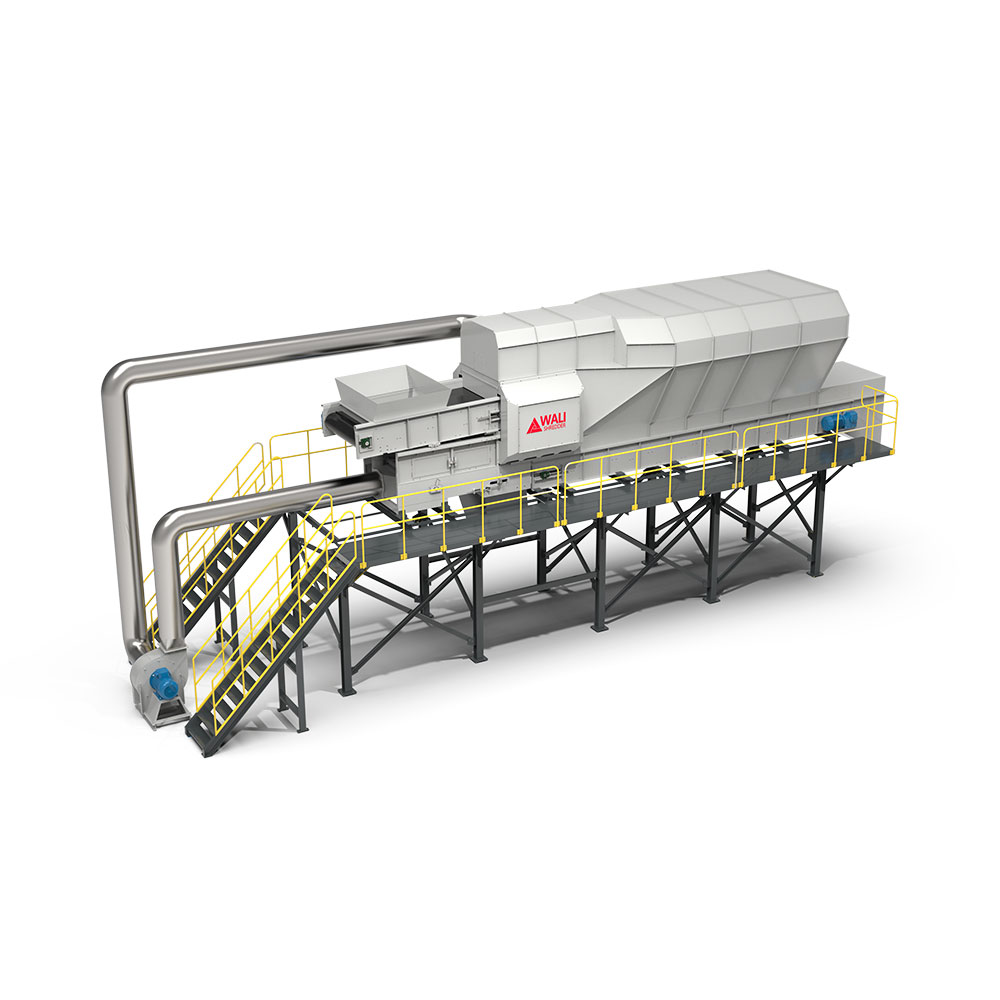

Car shredders

A car shredder is a machine used to dismantle and recycle old vehicles. It breaks down cars into smaller pieces, separating materials like metals, plastica, and glass for easier processing and recycling. The process often involves a powerful mechanical shredder equipped with rotating blades that cut through the car’s frame and components. These machines help reduce waste and promote the recycling of valuable materials from old vehicles.

Key Features of Car Shredders :

- Powerful Motors: High-capacity motors provide the necessary force to shred entire vehicles, typically ranging from hundreds to thousands of horsepower.

- Durable Blades: The shredder’s cutting elements, usually made from hardened steel, can withstand the wear and tear of processing heavy and abrasive materials.

- Feed System: Mechanisms such as conveyors or hydraulic feeders ensure that cars are fed into the shredder smoothly and efficiently.

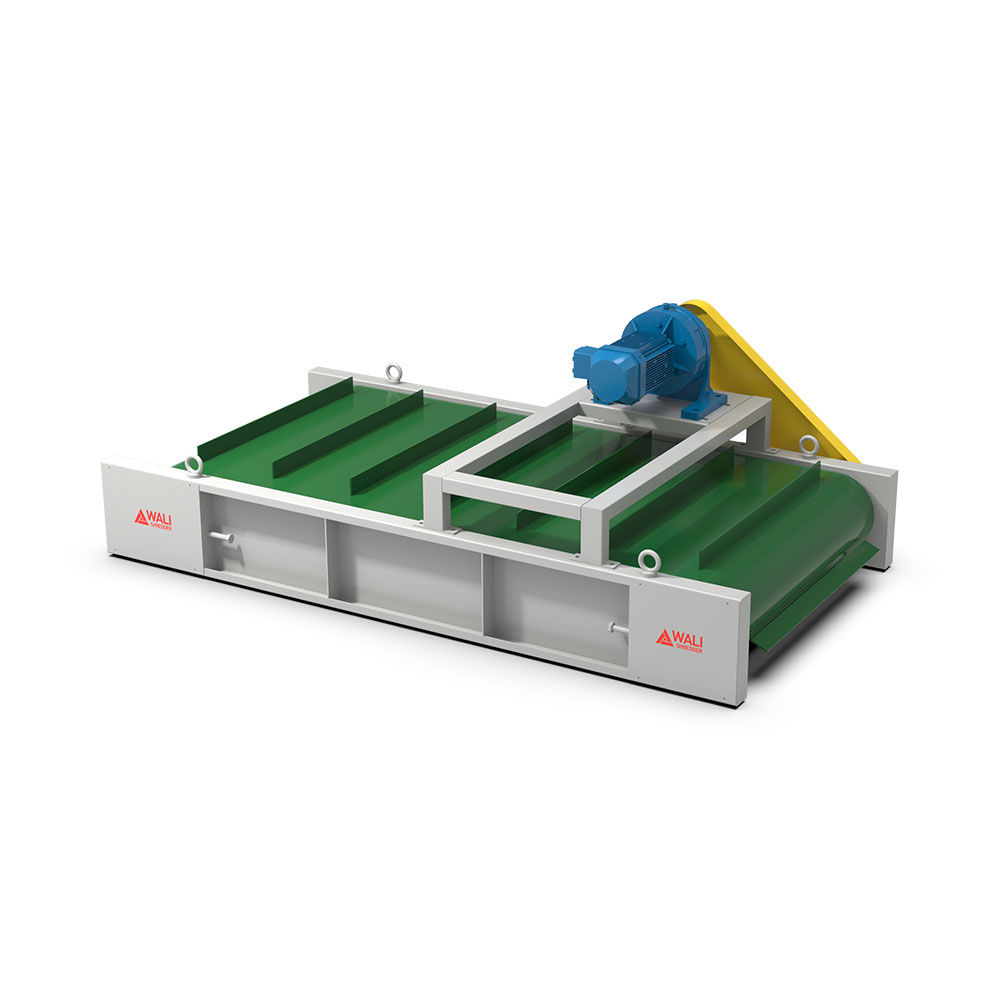

- Magnetic Separation: Built-in magnets help separate ferrous metals (iron and steel) from other materials during the shredding process.

- Eddy Current Separators: These are used to separate non-ferrous metals (like aluminum and copper) from the shredded material.

- Dust and Noise Control: Systems to manage dust and reduce noise pollution, ensuring compliance with environmental regulations and improving working conditions.

- Automated Control Systems: Modern shredders often include computerized controls to optimize performance, monitor operations, and ensure safety.

- Robust Construction: Heavy-duty frames and components provide stability and longevity, enabling the machine to handle the stresses of shredding vehicles.

- Safety Features: Includes emergency stop mechanisms, safety interlocks, and protective guards to ensure the safety of operators and maintenance personnel.

- Versatile Processing: Some shredders can handle a variety of materials beyond cars, such as household appliances, metal scrap, and industrial waste, adding flexibility to recycling operations.

How does Car Shredder Work?

A car shredder works through a multi-step process to dismantle and recycle old vehicles:

- Initial Preparation: The car is drained of fluids (oil, gas, coolant) and hazardous materials are removed. Components like batteries and tires are also taken off.

- Shredding: The prepared car is fed into the shredder. Inside the shredder, large rotating hammers or blades break the car into smaller pieces. The shredder’s powerful motors and cutting edges can handle a variety of materials, compreso l'acciaio, alluminio, and plastics.

- Sorting: Once shredded, the materials are passed through a series of separation processes:

- Magnetic Separation: Magnets extract ferrous metals (like steel and iron) from the mixture.

- Eddy Current Separation: This method is used to separate non-ferrous metals (like aluminum and copper) from other materials.

- Air Classification: Lighter materials, such as plastics and foam, are separated from heavier metals through air flow.

- Further Processing: The separated materials might undergo additional processing to refine them. For instance, metals can be melted down and purified for reuse, while plastics can be processed into pellets for manufacturing new products.

- Recycling: The processed materials are then sold to manufacturers and recyclers, who use them to create new products, closing the recycling loop and reducing the need for raw materials.

Factors Influencing Car Shredders Price

1. Car Shredder Configuration

- Blade Type and Material: Different shredders use various blade configurations and materials (e.g., steel) for durability and efficiency.

- Motor Power: Ranges from 50 HP to over 500 HP depending on the shredder’s size and capacity.

- Brand and Manufacturer: Reputable brands with a history of reliability and performance will significantly impact its cost.

- Customization: Machines tailored for specific applications or with special configurations may be more expensive.

2. Additional Costs

- Shipping and Transportation: Depending on the location, transporting a large tire shredder can add several thousand dollars to the total cost.

- Installation and Setup: Professional installation and setup will be an expense.

- Maintenance and Spare Parts: Ongoing maintenance and the cost of replacement parts should be factored into the overall budget.

FAQs about Car Shredders

Q:What are the benefits of car shredders?

A: Enables the extraction of valuable metals like steel, alluminio; reducing costs in transportation and storage.

Q: What is the price of a car shredder ?

A: The price of a Car Shredder can vary significantly depending on its size, capacity, discharge size, motor brands and so on.

Conclusion:

Car shredders are essential for resource recovery, helping to reduce waste and recycle materials efficiently.When choosing a car shredder, it’s essential to consider factors such as the type of materials, the volume of material, discharge size , installation space and budget.

Trituratore Guardiano

Trituratore Guardiano