What is a industrial paper shredder?

Table of Content

- Industrial Paper Shredder

- Key Features of Industrial Paper Shredder

- How Does An Industrial Paper Shredder work?

- Differences from Standard Office Shredders

- FAQs about Industrial Paper Shredder

- Conclusion

Industrial Paper Shredders

Industrial Paper Shredders are robust machines designed for high-volume shredding of paper and other materials in commercial or industrial settings.

Key Features of Industrial Paper Shredder

The key components of an industrial paper shredder are designed to ensure efficient, high-capacity shredding while maintaining safety and durability.

-

Feed Mechanism:

- Hopper: The entry point where paper and other materials are loaded. It can be a simple slot or a large bin.

- Conveyor Belt: Some industrial shredders use a conveyor belt to automatically feed materials into the shredding blades.

-

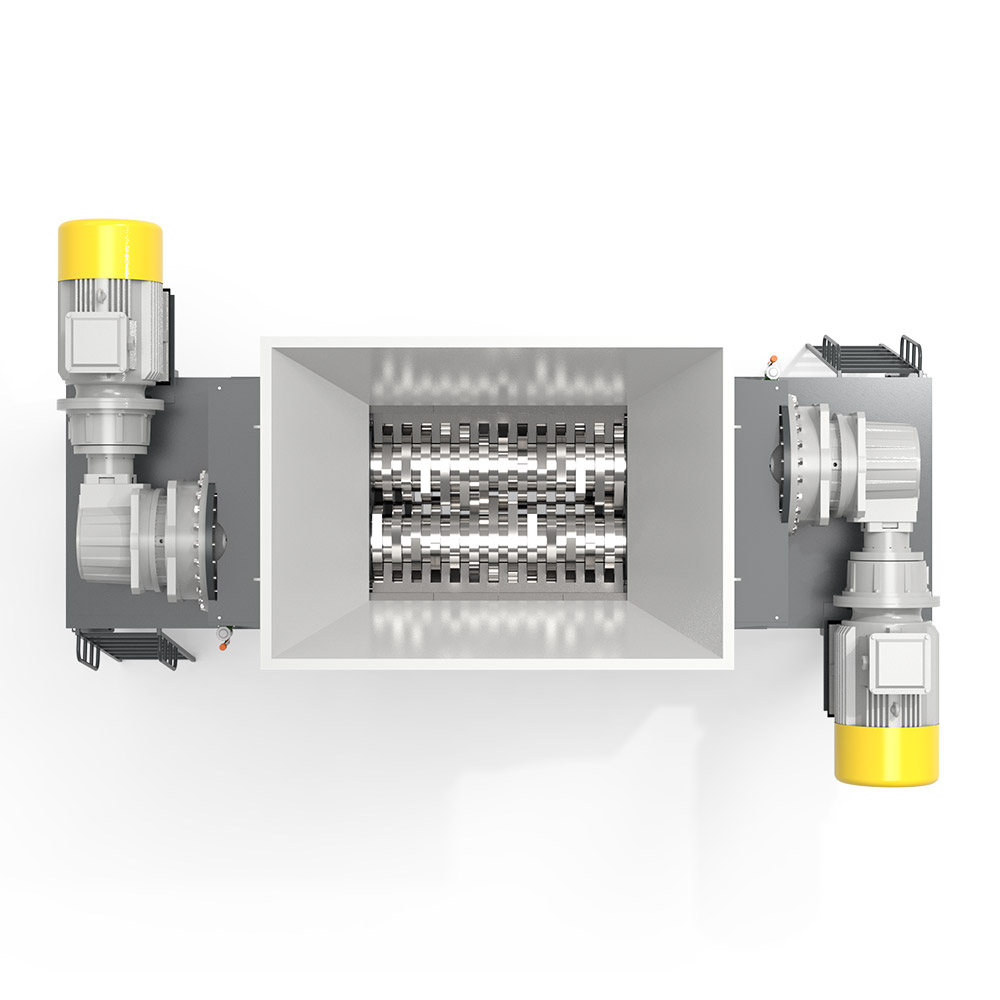

Cutting Mechanism:

- Rotating Blades/Shafts: These are the core components that shred the paper.

- Cutting Knives: Sharp blades attached to the rotating shafts that slice through the paper.

-

Motor:

- Power Source: A robust motor that provides the necessary power to rotate the blades and handle large volumes of paper and other materials.

- Drive System: Often includes gears and belts to transfer power from the motor to the cutting shafts.

-

Safety Features:

- Emergency Stop Button: Allows for immediate shutdown in case of an emergency.

- Safety Guards: Protective covers and barriers to prevent accidental contact with moving parts.

- Sensors: Detects jams, overloads, and other issues, triggering automatic shutdown or reverse operation to prevent damage.

-

Lubrication and Maintenance Systems:

- Self-Oiling Mechanism: Some shredders have automatic oiling systems to keep blades lubricated and functioning efficiently.

- Maintenance Alerts: Indicators or systems that notify when maintenance is required, such as oiling or blade sharpening.

-

Cooling System:

- Fans or Heat Sinks: Prevents the motor and other components from overheating during continuous operation.

-

Additional Features:

- Jam-Resistant Mechanisms: Technologies to prevent or clear jams, such as reverse functions and auto-shutoff.

- Noise Reduction: Insulation and design features to minimize operational noise.

- Dust Extraction: Systems to manage and reduce dust produced during shredding, ensuring a cleaner working environment.

How does an Industrial Paper Shredder Work?

-

Shredding Process:

- As the paper is fed into the shredder, it is grabbed by the rotating blades.

- The blades rotate in opposite directions, pulling the paper through and slicing it into pieces.

- The shredded material falls into a collection bin or is transported away by a conveyor system.

-

Output and Collection:

- The shredded paper is collected in a large bin or bag for disposal or recycling.

- Some industrial shredders are equipped with balers or compactors that compress the shredded material into bales for easier handling and transport.

-

Safety and Jam Prevention:

- Many industrial shredders have safety features like emergency stop buttons, safety guards, and sensors to detect jams.

- If a jam is detected, the shredder may automatically reverse the blades to clear the blockage and prevent damage to the machine.

Differences from Standard Office Shredders

- Capacity and Speed: Industrial shredders can handle larger quantities of paper at a faster rate, often shredding hundreds of sheets at once.

- Durability: Built to withstand continuous use, these machines are made from heavy-duty materials and are designed to be more durable than their office counterparts.

- Security Levels: They offer various security levels, from basic strip-cut to high-security cross-cut and micro-cut, ensuring that shredded documents cannot be reconstructed.

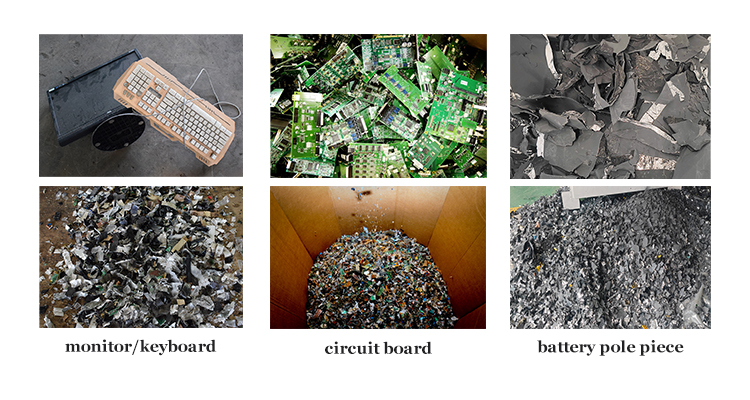

- Versatility: Many Industrial Paper Shredder can also shred other materials like plastic,paper clips, CDs, DVDs, and credit cards, making them versatile for various shredding needs.

- Size and Power: These shredders are larger and more powerful, requiring more space and sometimes a dedicated power supply.

In summary, the biggest difference between Industrial Paper Shredders and standard office paper shredders is that Industrial Paper Shredders can shred materials other than paper, including plastic, e-waste, wood, metal.

Factors Influencing Industrial Paper Shredders Price

1.Industrial Paper Shredders Configuration

- Blade Type and Material: Different shredders use various blade configurations and materials (e.g., steel) for durability and efficiency.

- Motor Power: Ranges from 50 HP to over 500 HP depending on the shredder’s size and capacity.

- Brand and Manufacturer: Reputable brands with a history of reliability and performance will significantly impact its cost.

- Customization: Machines tailored for specific applications or with special configurations may be more expensive.

2. Additional Costs

- Shipping and Transportation: Depending on the location, transporting a large tire shredder can add several thousand dollars to the total cost.

- Installation and Setup: Professional installation and setup will be an expense.

- Maintenance and Spare Parts: Ongoing maintenance and the cost of replacement parts should be factored into the overall budget.

FAQs about Industrial Paper Shredders

Q:What are the benefits of Industrial Paper Shredders ?

A: Facilitating resource recovery, reducing costs in transportation and storage.

Q: What is the price of a Industrial Paper Shredders ?

A: The price of a Plastic shredder can vary significantly depending on its size, capacity, discharge size, motor brands and so on.

Conclusion

Overall, industrial paper shredders are designed to be robust, efficient, and safe, making them ideal for large-scale shredding operations in businesses, government agencies, and recycling centers.

When choosing a industrial paper shredder, it’s essential to consider factors such as the type of materials, the volume of material, discharge size, installation space and budget.

Wali Shredder

Wali Shredder