What is a e-waste shredder?

Table des matières

- E-waste Shredders

- Types of E-waste Shredders

- Key Features of E-waste Shredders

- Safety and Maintenance

- Applications

- Advances

- Factors Influencing E-waste Shredders Price

- FAQs about E-waste Shredders

- Conclusion

E-waste Shredders

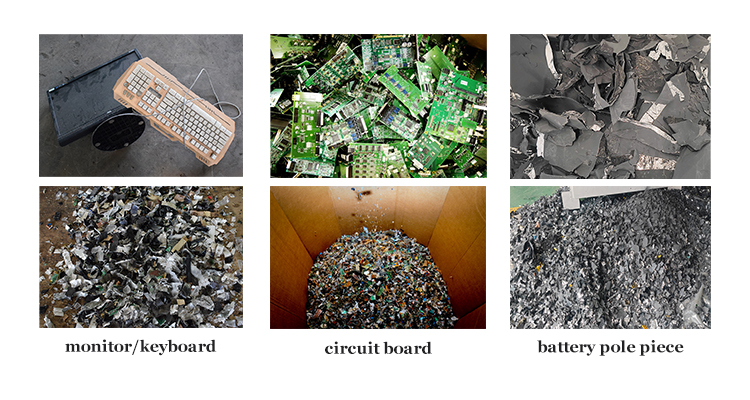

E-waste shredders are specialized machines designed to process electronic waste (e-waste) by shredding it into smaller, pièces gérables. This is an important step in the recycling process as it helps to separate valuable materials from hazardous components, making it easier to recycle and dispose of electronic waste safely and efficiently.

by shredding it into smaller, pièces gérables. This is an important step in the recycling process as it helps to separate valuable materials from hazardous components, making it easier to recycle and dispose of electronic waste safely and efficiently.

Types of E-waste Shredders:

- Déchiqueteuses à arbre unique: Use a single rotating shaft with blades to cut materials.

- Déchiqueteuses à double arbre: Have two shafts with interlocking blades for more thorough shredding.

- Déchiqueteuses à quatre arbres: Utilize four shafts for even finer shredding and separation of materials.

Key Features of E-waste Shredders

1.Durability and Robustness:

- Heavy-Duty Construction: Built with strong materials to withstand the rigors of shredding tough and dense electronic waste.

- Wear-Resistant Blades: Equipped with blades made from high-strength steel or other durable materials to ensure longevity and consistent performance.

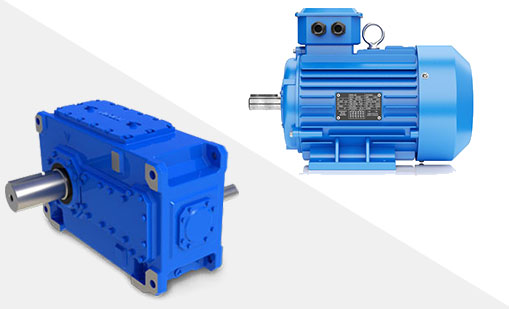

2.Efficiency and Throughput:

- High Capacity: Designed to handle large volumes of e-waste, allowing for efficient processing.

- Powerful Motors: Equipped with high-power motors to ensure efficient and effective shredding of various types of electronic materials.

3.Adjustable Settings:

- Variable Speed Controls: Allows for adjustment ofshredding speed to optimize for different types of e-waste.

- Customizable Blade Configurations: Blades can be arranged and customized to handle specific types of electronic materials more effectively.

4. Noise and Dust Control:

- Noise Reduction Features: Designed to operate with minimal noise, making them suitable for indoor use and reducing noise pollution.

- Dust Suppression Systems: Equipped with systems to control dust and debris, ensuring a cleaner and safer working environment.

5. Automation and Integration:

- Automated Feeding Systems: Includes conveyors and other mechanisms to automatically feed e-waste into the shredder, enhancing efficiency and reducing manual labor.

- Integration with Sorting Systems: Can be integrated with sorting and separation systems to streamline the recycling process

Safety and Maintenance:

1.Safety:

- Emergency Stop Mechanisms: Includes easily accessible emergency stop buttons to quickly halt operations in case of an emergency.

- Safety Guards and Shields: Protects operators from flying debris and accidental contact with moving parts.

2.Maintenance:

- Modular Design: Components are designed to be easily accessible and replaceable, simplifying maintenance and repairs.

Applications:

- Recycling Facilities: Used to process e-waste for material recovery.

- IT Asset Disposal: Helps in securely disposing of outdated or non-functional electronic devices.

- Municipal Waste Management: Employed by cities and municipalities for managing electronic waste.

Advances:

- Reduction in Size: Shredders reduce the size of e-waste, making it easier to handle and process.

- Separation of Materials: They help in separating different materials such as metals, matière plastique, and glass.

- Data Destruction: Shredding can ensure the destruction of sensitive data stored on electronic devices.

- Reducing Landfill Waste: Shredding helps in diverting e-waste from landfills.

- Resource Recovery: Enables the extraction of valuable metals like gold, silver, and copper from e-waste.

- Hazardous Waste Management: Helps in safely handling and disposing of hazardous components like batteries and toxic chemicals.

Factors Influencing E-waste Shredders Price

1.E-waste Shredders Configuration

- Type et matériau de la lame: Différents broyeurs utilisent différentes configurations de lames et de matériaux (Par ex., acier) pour la durabilité et l’efficacité.

- Puissance du moteur: Gammes de 50 HP à plus de 500 HP en fonction de la taille et de la capacité de la déchiqueteuse.

- Marque et fabricant: Les marques réputées ayant un historique de fiabilité et de performance auront un impact significatif sur son coût.

- Personnalisation: Les machines adaptées à des applications spécifiques ou avec des configurations spéciales peuvent être plus chères.

2.Coûts supplémentaires

- Expédition et transport: Selon l’emplacement, Le transport d’une grosse déchiqueteuse de pneus peut ajouter plusieurs milliers de dollars au coût total.

- Installation et configuration: L’installation et la configuration professionnelles seront une dépense.

- Maintenance et pièces de rechange: L’entretien continu et le coût des pièces de rechange doivent être pris en compte dans le budget global.

FAQs about E-waste Shredders

Q:What are the benefits of E-waste Shredders ?

Un: Enables the extraction of valuable metals like gold, silver, and copper from e-waste;Réduction des coûts de transport et de stockage.

Q: What is the price of a E-waste Shredder ?

Un: The price of a e-waste shredders can vary significantly depending on its size, capacité, Taille de la décharge, marques de moteurs, etc..

Conclusion:

E-waste shredders play a crucial role in managing electronic waste, ensuring that valuable materials are recovered, and hazardous components are disposed of safely.When choosing a e-waste shredder, it’s essential to consider factors such as the type of materials, the volume of material, Taille de la décharge , installation space and budget.

Déchiqueteuse Wali

Déchiqueteuse Wali