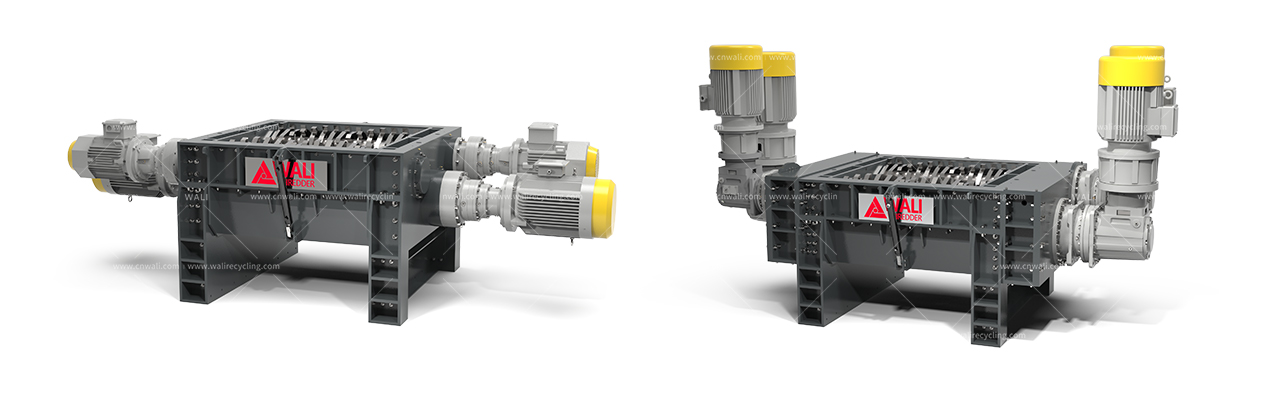

Wali Four-shaft Shredder Introduction

Introduction

Four-shaft shredder is a device to reduce waste materials to homogeneous particle sizes whether as a stand-alone solution or as part of recycling system. It combines the reliability and power of the double-shaft shredders with the possibility of controlling the output material size.

Four-axis shredder can tear and shatter efficiently without auxiliary press mechanism and perfect for handling frame waste and tough material.The the function of the two cutters above the four-shaft shredder is to clean the shafts below and at the same time provide a certain amount of shearing force.

The size of the output material is controlled by the screen. After the material is cut once, the material with a smaller particle size than the hole of the screen is discharged from the lower part of the box under the action of gravity and squeezing pressure, while the material with a larger size than the hole of the screen is guided by the main cutters and the secondary cutters to return to the inner surface of the screen for the second cutting, and so on until the material can be discharged from the hole of the screen.

Ventajas

In the solid waste recycling industry, the four-axis shredder has great advantages.

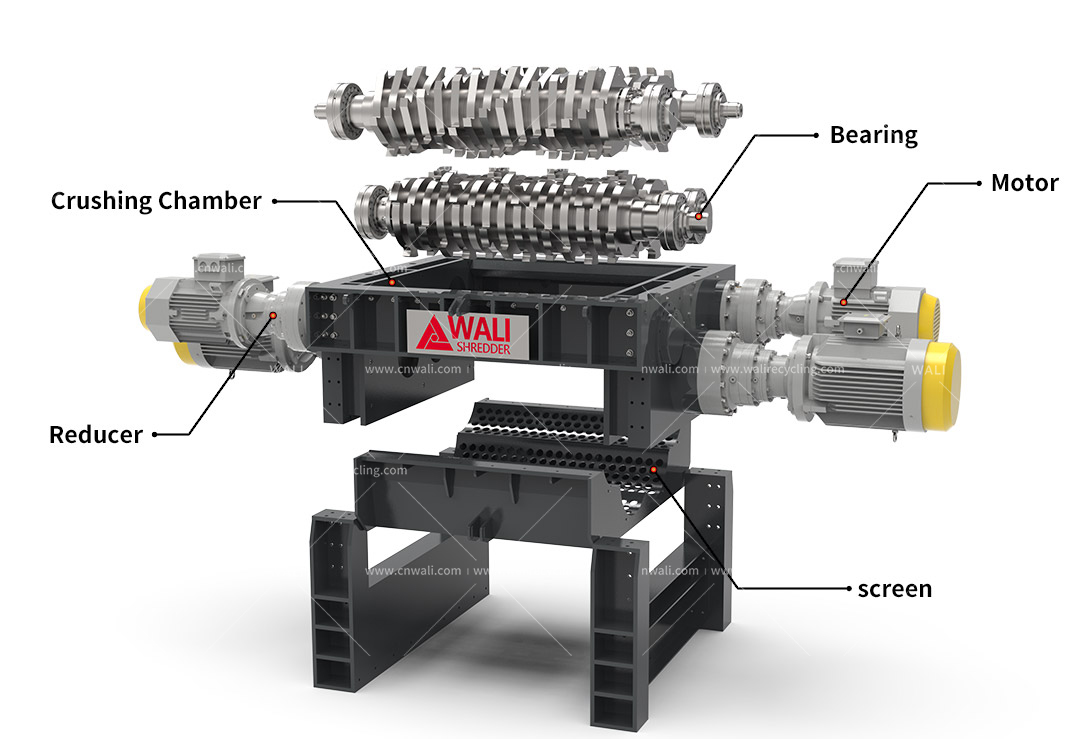

Cutter

Blades are made of special alloy steel with wear-resistant and are convenient for replacement and maintencance; spindles are made of 42CrMo high alloy stell and refined by multiple processes, high mechanical strength, high fatigue and impact resistance and long life.

Pantalla

The four-axis shredder is equipped with a sieve at the bottom of the crushing chamber to circulate the material until the required particle size is reached.

Drive system

Adopting double motors and heavy-load planetary reducer realize low speed and high torgue, improving high strength shattering and tearing.

Bearing

The bearing has a quadruple sealing protection design which makes it dust proof and waterproof, effectively prolonging the service life of the bearing and suitable for harsh working environment.

Automatic overload protection

Seted safety current to re-orients rotor direction when motor overload or material jam, protecting the motor from being damaged.

Sistema de control PLC

The electric cabinet is equipped with a Siemens/Schneider PLC. El sistema de control PLC puede realizar monitoreo en tiempo real, Alarma anormal, Diagnóstico remoto y análisis de datos.

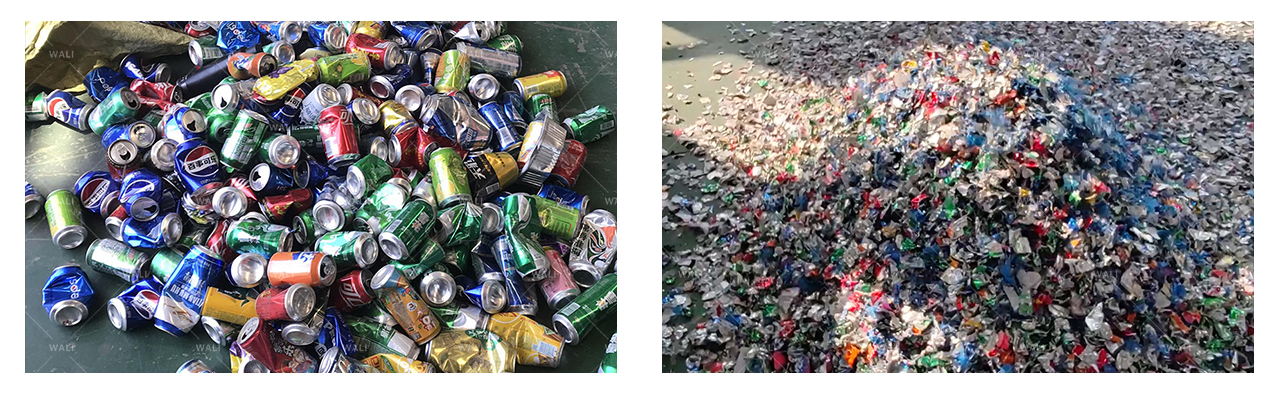

Applications

Four-shaft shredders are widely used in the treatment of various types of industrial waste, including but not limited to the following areas:

+Barrel products: plastic barrels, metal barrels, paint barrels, IBC barrels, trash cans, etc.

+Solid waste: bulky waste, domestic waste, industrial waste, garden waste, etc.

+Plastic products: Palets de plástico, plastic bottles, plastic frames, plastic blocks, plastic containers, etc.

+Metal products: aluminum alloy, waste aluminum castings, oil filters, car shells, Latas, etc.

+Papel: periódicos, cartón, corrugated paper, copy paper,etc.

+Electronic appliances: Refrigeradores, circuit boards, TV shells, small appliance shells, Discos compactos, etc.

+Glass products: glass wool, glasses, glass bottles, etc.

+Paper mill waste: paper mill light residue, paper mill rope, paper mill scraps, etc.

Conclusión

Four shaft shredders are the result of an innovative design that aim to create efficient and flexible machines.

They combine the features of double shaft shredder with the use of wear-proof screens, which drastically reduced the management and maintenance costs.

And they can be designed according to the user’s requirements and the materials to be processed to maximize the user’s benefit.

Trituradora Wali

Trituradora Wali