¿Qué es una trituradora de cables??

Tabla de contenido

- A Cable Shredder

- Key Features of Cable shredders

- How does A Cable shredder Work?

- Factors Influencing Cable Shredders Price

- FAQs about Cable Shredders

- Conclusión

A Cable Shredder

A cable shredder is a machine designed to shred and process cables and wires. These shredders are used in recycling facilities to separate valuable materials such as copper and aluminum from the insulation and other non-metallic components. The shredded cables are then processed further to recover these valuable metals, which can be reused in various industries. Using a cable shredder helps in efficiently recycling electronic waste and reducing environmental pollution.

Key Features of Cable shredders

-

Shredder Type:

- Trituradora de un solo eje: Suitable for handling consistent and less complex cable types.

- Dual-Shaft Shredder: Ideal for processing larger volumes and more complex or mixed materials.

-

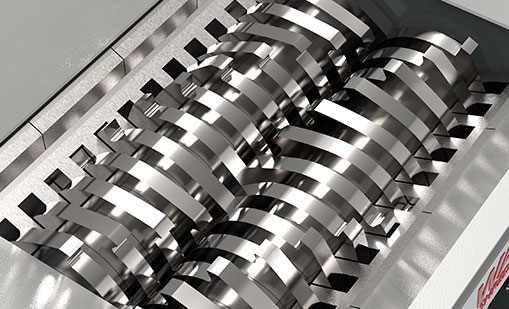

Cutting System:

- Blade Design: Different blade shapes and materials (p ej., hardened steel) for various cable types.

- Adjustable Blades: Allows for customization of shred size.

-

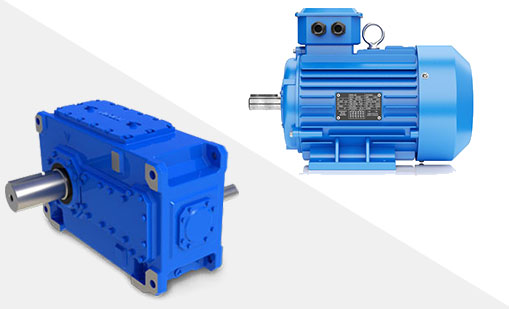

Potencia del motor:

- High-Torque, Low-Speed Motors: Provide the necessary force to shred tough materials without overheating.

-

Feeding Mechanism:

- Tamaño de la tolva: Depending on the volume of cables being processed.

- Conveyor Belt: For continuous feeding and higher efficiency.

-

Control System:

- Automation and Monitoring: Systems to monitor performance, detect jams, and adjust operations.

- User Interface: Easy-to-use control panels with emergency stop functions.

-

Safety Features:

- Emergency Stop Buttons: Strategically placed around the machine.

- Safety Guards: To protect operators from moving parts.

- Overload Protection: To prevent damage to the machine.

-

Capacity and Throughput:

- Shredding Capacity: Based on the expected volume and type of cables to be processed.

- Throughput Speed: Adjustments to balance processing speed and efficiency.

-

Energy Efficiency:

- Energy-Saving Modes: To reduce power consumption during idle times.

How does A Cable shredder Work?

A cable shredder operates through a series of steps designed to efficiently break down and separate the components of cables and wires:

-

Feeding:

Cables and wires are fed into the shredder through a hopper or conveyor belt.

-

Shredding:

The shredder has rotating blades or cutting drums that chop the cables into smaller pieces. This process can involve multiple stages, with each stage further reducing the size of the material.

-

Separation:

After shredding, the material is typically passed through various separation processes:

- Magnetic Separation: Magnetic separators are used to remove any ferrous (iron-based) metals from the shredded material.

- Air Classification: An air separator may be used to separate lighter plastic or rubber materials from heavier metal particles.

- Eddy Current Separation: This technique uses magnetic fields to separate non-ferrous metals (like aluminum and copper) from other materials.

-

Collection:

The separated materials are collected in different bins or containers for further processing or direct recycling.

-

Refinement:

The metals can undergo additional refinement processes to purify them further and prepare them for reuse in manufacturing.

This entire process not only facilitates the recycling of valuable metals but also ensures that hazardous materials are properly managed and disposed of, reducing environmental impact.

Factors Influencing Cable Shredders Price

1. Cable Shredder Configuration

- Tipo de cuchilla y material: Las diferentes trituradoras utilizan varias configuraciones de cuchillas y materiales (p ej., acero) para durabilidad y eficiencia.

- Potencia del motor: Oscila entre 50 HP a más de 500 HP dependiendo del tamaño y la capacidad de la trituradora.

- Marca y fabricante: Las marcas de renombre con un historial de confiabilidad y rendimiento tendrán un impacto significativo en su costo.

- Personalización: Las máquinas diseñadas para aplicaciones específicas o con configuraciones especiales pueden ser más caras.

2. Costos adicionales

- Envío y transporte: Dependiendo de la ubicación, El transporte de una trituradora de neumáticos grande puede agregar varios miles de dólares al costo total.

- Instalación y configuración: La instalación y configuración profesional será un gasto.

- Mantenimiento y repuestos: El mantenimiento continuo y el costo de las piezas de repuesto deben tenerse en cuenta en el presupuesto general.

FAQs about Cable Shredders

Q:What are the benefits of cable shredders?

Un: Enables the extraction of valuable metals like copper, aluminio; Reducción de costes en transporte y almacenamiento.

Q: What is the price of a cable shredder ?

Un: The price of a cable shredder can vary significantly depending on its size, capacidad, Tamaño de la descarga, marcas de motores, etc.

Conclusión

Cable shredders are essential for resource recovery, helping to reduce waste and recycle materials efficiently. When purchasing a cable shredder, it’s important to consider factors such as the type and volume of cables we need to process, the machine’s capacity and features, after-sales support, and warranty.

Trituradora Wali

Trituradora Wali