What is a metal shredder?

Inhaltsverzeichnis

- Metall-Aktenvernichter

- Types of Metal Shredders

- Key Components of Metal Shredders

- Applications of Metal Shredders

- Safety and Maintenance

- FAQs about Metal Shredders

- Schlussfolgerung

Metal Shredders

A metal shredder is a machine designed to reduce the size of metal waste into smaller, manageable pieces for recycling or disposal. These shredders are used in various industries, including automotive, manufacturing, and waste management. Here’s an overview of metal shredders:

Types of Metal Shredders

-

Hammer Mills

- Description: Use hammers mounted on a rotating shaft to crush and shred metal.

- Anträge: Suitable for light to medium-duty shredding, such as aluminum cans, light metal scraps, and small automotive parts.

-

Granulators

- Description: Use rotary knives and stationary knives to cut metal into small granules.

- Anträge: Often used for precise shredding of smaller metal parts and electronic waste.

-

Single-Shaft Shredders

- Description: Feature a single shaft with rotary blades to shred metal.

- Anträge: Suitable for a wide range of metal shredding tasks, providing flexibility in processing various types of metal waste.

-

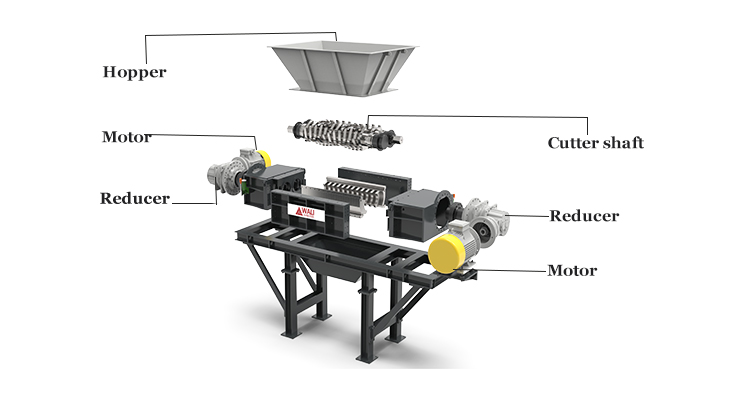

Double-Shaft Shredders

- Description: Use two shafts with interlocking blades to shred metal.

- Anträge: Commonly used for bulky metal items and are capable of handling tougher materials.

Key Components of Metal Shredders

-

Hopper

- Function: Feeds metal waste into the shredder.

- Design: Often designed to accommodate large and irregularly shaped metal pieces.

-

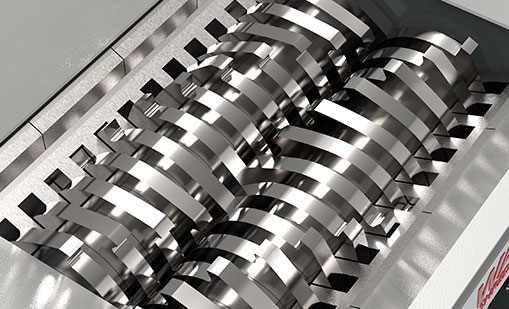

Rotary Blades or Hammers

- Function: Perform the actual shredding of metal.

- Material: Made from hardened steel or other durable materials to withstand the toughness of metal.

-

Motor

- Function: Powers the shredder, typically through an electric or hydraulic system.

- Power Rating: Varies depending on the shredder’s capacity and intended use.

-

Cutting Chamber

- Function: Houses the blades or hammers and facilitates the shredding process.

- Design: Constructed to handle high impact and resist wear.

-

Discharge System

- Function: Removes shredded metal from the shredder.

- Types: Can include conveyors, or bins.

Applications of Metal Shredders

-

Automotive Recycling

- Use: Shredding old vehicles, including car bodies, engines, and other parts for recycling.

- Outcome: Recovered metals are sorted and processed for reuse.

-

Scrap Metal Processing

- Use: Shredding various types of scrap metal from manufacturing and demolition.

- Outcome: Metal is prepared for smelting and recycling.

-

Electronic Waste (E-Waste) Recycling

- Use: Shredding electronic devices to recover valuable metals like copper, Aluminium, and gold.

- Outcome: Metals are separated from other materials for recycling.

-

Waste Management

- Use: Reducing the volume of metal waste in municipal and industrial waste streams.

- Outcome: Shredded metal is easier to transport and process.

Safety and Maintenance

-

Safety Features

- Emergency Stop: Immediate shutdown capability in case of an emergency.

- Safety Guards: Protect operators from moving parts.

- Sensors: Detect blockages and prevent damage.

-

Maintenance

- Regular Inspections: Ensure components are in good working condition.

- Blade Sharpening/Replacement: Maintain sharp blades for efficient shredding.

- Lubrication: Keep moving parts well-lubricated to prevent wear and tear.

FAQs about Metal Shredder

Q: What are the benefits of Metal Shredders?

Ein: Significantly lowers transportation and disposal costs by reducing the size and the need for landfill space; Facilitates the recovery and recycling of valuable metals.

Q: What is the price of a Metal Shredder?

Ein: The price of a metal shredder can vary significantly depending on its size, the type of materials we need to shred, discharge size, motor brand, blade material and so on.

Schlussfolgerung

By incorporating metal shredders into waste management and recycling operations, industries can improve their sustainability practices, recover valuable materials, and reduce environmental impact. When choosing a metal shredder, it’s essential to consider factors such as the type of materials, the volume of material, discharge size , blade material, installation space and budget.

Wali Aktenvernichter

Wali Aktenvernichter