Characteristics and advantages of Wali single shaft shredder

Single shaft shredder introduction:

Single shaft shredder with a single shaft can commonly used in waste recycling. It is available to recycle wide range of material and an ideal machine for plastic, paper, wood, fiber, rubber, organic waste a wide variety of non-metallic materials.

Compare to double shaft shredder, it is equipped with a sieve, allowing the control the output sizes. It can work as a stand-alone or be uesd in recycling production line.

According to market demand and actual application conditions, three different types of single shaft shredders lunched by Wali are available for various needs.

Here is the features of single shaft shredders:

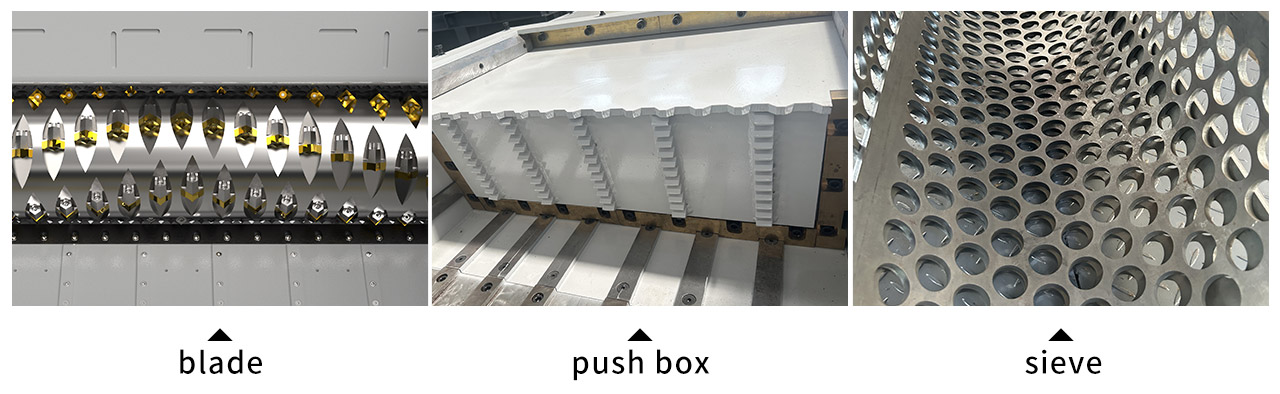

1.Rotor Blades

The rotating shaft is arranged in a V-shape, and the blade is installed on the knife holder, which is welded to the rotor. This design can reduce the feeding resistance when crushing materials. The cutter is made of wear-resistant and corrosion-resistant alloy steel. The blade can be adjusted many times to maximize the use of the blade.

2.Single shaft shredder screen

It is a special design of single shaft shredder, and we can control the output particle size by choosing desired sieve to fit various needs.

3.Flat Push box

Segmented shredding chamber floor with brass guides is more wear-resistant and keep smooth pushing. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components.

4. Inclined push box

Driving by hydraulic pressure, this design can reduce no-load loss, ensuring high efficiency pushing and shredding performance.

5.PLC controlling system

The main electrical components of dual shaft shredder are trusted brands such as Siemens and Schneider. PLC controlling system can realize real-time monitoring, abnormal alarm, remote diagnosis and data analysis.

6.Auto-reverse system

Auto-reverse system re-orients rotor direction when motor overload or material jam.

7.Curved access door

Opening the access door by hydraulic device, it is more easy and convenient during maintenance, saving time and costs.

8.Low operation and maintenance cost

With a rational design, single shaft shredders are simple to operate and maintain, making it easy for users to master their operation and maintenance.

Application:

Single shaft shredders are widely used in the treatment of various types of industrial waste, including but not limited to the following areas:

+ Plastics: Mouldings, purging/lump, profiles, films, etc.

+ Timber/Wood: Pallets, joiners waste, green waste, etc.

+ Paper & Cardboard: Confidential documents, production Waste, packaging materials,etc.

+ Copper Cable: Household, telecoms, and industrial cables, etc.

+ Aluminum: Used beverage cans (UBCs), swarf, cables, etc.

+Textiles: Carpet (Rols & Tiles), garments, etc.

+ Security Destruction: Counterfeit items, faulty goods, out of date stock, etc.

+ Foam: Production waste, etc.

+ Mixed Household & Commercial Waste: RDF/SRF Production.

Conclusion:

Single shaft shredders are essential for resource recovery, helping to reduce waste and recycle materials efficiently. As a manufactuer in this industry with more ten years, we have rich experience and can cater for your any requirements.

Wali Shredder

Wali Shredder